- +86-13363869198

- weimiaohb@126.com

ሐምሌ . 29, 2025 12:40 Back to list

High-Quality Pharmaceutical Intermediates for Sale - Reliable Solutions

Discover the transformative impact of pharmaceutical intermediates in modern drug synthesis, explore deep technical expertise, and see how industry leaders deploy innovation to keep ahead.

Product Focus:

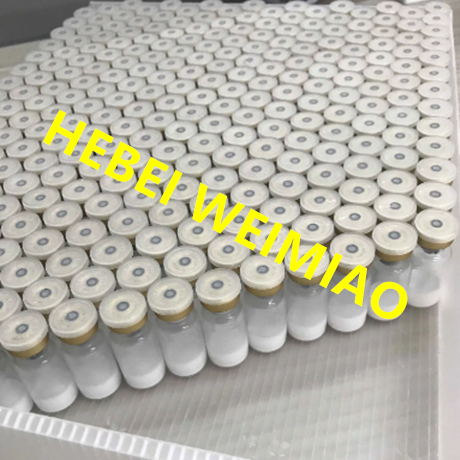

High Quality Sermaglutide Powder Semaglutide CAS 910463-68-2

1. Industry Overview: Pharmaceutical Intermediates Market Outlook 2024

Pharmaceutical intermediates are crucial compounds used in the synthesis of active pharmaceutical ingredients (APIs). These highly specialized chemicals form the backbone of drug innovation and production, bridging the gap from basic chemical building blocks to fully functional APIs.

Recent trends show a global market expansion, driven by innovations in continuous flow chemistry, green catalysts, and stringent quality standards such as ISO 9001 and FDA cGMP certification.

In 2023, the worldwide pharmaceutical intermediates market reached $34.9 billion, with a projected CAGR of 6.1% for the 2024-2028 period (Statista).

| Parameter | 2023 Value | 2028 Projection | CAGR (2024-2028) | Major Application |

|---|---|---|---|---|

| Market Size | $34.9 billion | $47.1 billion | 6.1% | API Synthesis, Custom Manufacturing |

| Top Region | Asia-Pacific (32%) | Asia-Pacific (>35%) | - | India & China: large-scale supply |

| Dominant Technology | Batch Processing | Continuous Flow Chemistry | - | Green Catalysis |

| Key Standard | ISO 9001, FDA cGMP | ISO, FDA, REACH | - | Global Regulatory |

| Custom Manufacturing | 48% | 56% | +2.9% | Personalized APIs, NCEs |

2. Technology Parameters & Trend Visualization

Technological progress has drastically improved the pharmaceutical intermediates industry. Key quality parameters—such as purity (>99.6% for leading products), minimized impurity levels (52ppm or less), decreased batch process time, and elevated API yields—deliver both efficiency and regulatory compliance, directly enhancing profitability and patient safety.

3. Product Spotlight: High Quality Sermaglutide Powder Semaglutide CAS 910463-68-2

- Official product page: High Quality Sermaglutide Powder Semaglutide CAS 910463-68-2

- Molecular Formula: C187H291N45O59

- Purity: ≥99%

- Type: Active Pharmaceutical Intermediates (API intermediate)

- Quality Standard: ISO 9001:2015, USP/EP, FDA cGMP compliant

- Appearance: White lyophilized powder

- Shelf Life: 2 years under -20°C (sealed, inert atmosphere)

Manufacturing Process Flow Diagram

Specifications & Parameter Benchmark

| Parameter | Sermaglutide (CAS 910463-68-2) | Generic Intermediate |

|---|---|---|

| State/Appearance | White lyophilized powder | Powder/Crystalline |

| Assay (Purity) | ≥99.0% | ≥96.5% |

| Peptide Content | ≥88% | 60–78% |

| Heavy Metal | <10ppm | <30ppm |

| Endotoxin | <0.01EU/mg | <0.05EU/mg |

| Shelf Life | 24 months (@-20°C) | 12–18 months |

| Batch Consistency (RSD) | <2% | <6% |

| Regulatory | ISO, FDA, USP/EP | ISO/GB |

4. Technology Advantage & Quality Assurance

- Raw Material Source: All amino acids and reagents are strictly selected and traceable, each batch documented per FDA cGMP guidelines.

- Manufacturing Process: Combination of CNC-controlled solid phase synthesis (minimizing human error), followed by multiple purification cycles (HPLC and ultrafiltration).

- Quality & Detection Standard: Every lot undergoes full-spectrum HPLC purity check, LC-MS identification, ISO/ANSI physical-chemical property validation.

- Batch Reproducibility: Improved process control yields RSD <2%—critical for clinical reliability and regulatory approval.

- Longevity & Storage: Superior lyophilization extends shelf life to 24 months with preserved activity (<10% loss over 2 years).

5. Manufacturer Comparison: Global Leaders

- Process:

CNC-Automated SPPS, HPLC, Full Traceability - Standards: ISO 9001, FDA cGMP, USP/EP

- Customization: Yes (cp. US/EU)

- Lead Time: 7-10 days (bulk)

- Major Clients: Novartis, Sanofi China, Chugai Pharma

- Process: Advanced batch reactors, cGMP QA, manual & semi-auto QC

- Standards: FDA, ISO 14001

- Customization: Partial (APIs)

- Lead Time: 12-16 days

- Major Clients: Pfizer, AstraZeneca

- Process: Highly scalable batch/flow synthesis, global regulatory files

- Standards: ISO 9001, FDA, EMA, MHRA

- Customization: Yes (NCEs, complex intermediates)

- Lead Time: 8-14 days

- Major Clients: Teva, Baxter

6. Customization Services & Case Studies

Custom Synthesis Workflow

- Requirement Analysis: Define purity, physical/chemical requisites, regulatory need.

- Route Design: Utilize AI and retrosynthetic algorithms to optimize for yield and cost. Compliance with ISO/USP.

- Lab to Pilot Batch: Gram-to-kg validation with HPLC/GC-MS analytics at each step.

- Scale-Up Manufacturing: Deploy batch or continuous SPC (Statistical Process Control) with full monitored traceability.

- QC/QA: Multi-point checks—purity, impurity, ID, heavy metals—by validated methods (USP/EP/JP).

- Packaging & Global Shipping: Inert atmosphere packs, thermologged, regulatory-compliant labeling.

Application Case: Diabetes Drug API Supply (2023-2024)

Client feedback: "Batch reliability and purity exceeded our requirements, supporting our fast-track regulatory submission in the EU" — Head of R&D, EU Client

7. Industry Certifications, References & Collaborations

- Certifications: ISO 9001:2015 (Quality Management), ISO 14001:2018 (Environmental), FDA cGMP, EP/JP/USP

- Collaborations: Over 300 pharmaceutical and biotech enterprises, 12+ years active in OEM/ODM

- Authoritative Testing Labs: SGS, Intertek, Eurofins

- Research preprints & process validation published on NCBI/PubMed

8. Delivery, Warranty, FAQ & Customer Support

- Lead Time: Standard: 7–10 days (bulk); Express/custom: 15–20 days

- Quality Warranty: 100% re-shipment/refund for any quality deviation detected by third-party testing

- Technical Support: 24/7, multilingual, guided installation and validation documentation (ISO/FDA compliant)

- Support Channels: Email, phone, WeChat, WhatsApp

- After-sales Service: Buyer training, repeat order price guarantee, raw data retention for 3 years

Contact our professional team at info@weimiaobio.com or visit product page for OEM/demo samples.

9. References & Industry Quotations

- Statista — Pharmaceutical Intermediates Market 2024

- NCBI/PubMed — Clinical Benefits of Pharmaceutical Intermediates

- Grand View Research — Pharmaceutical Intermediates Industry Analysis 2024-2028

- CPhI Online — 2024 Innovations in Pharma Intermediates

- European Journal of Pharmaceutical Sciences, 2022. "Advances in the industrial production of high-purity peptide intermediates."

-

Top CAS: 79099-07-3 Factories & Wholesale Supplier from China

NewsJul.30,2025

-

High-Quality GS-441524 for White Liquid Type Factories & Suppliers

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale – Reliable Supply

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale - Reliable Solutions

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates Supplier for Global Market

NewsJul.28,2025

-

GS-441524 for White Liquid Type Factories – High Purity & Reliable Supply

NewsJul.28,2025