- +86-13363869198

- weimiaohb@126.com

Sep . 15, 2025 15:19 Zurück zur Liste

Premium GS-441524 for White Liquid Type Factories - Purity Assured

Industry Trends and the Evolving Landscape for GS-441524 Production

The global veterinary pharmaceutical market is experiencing robust growth, driven by increasing pet ownership, advancements in animal healthcare, and a heightened focus on companion animal well-being. Within this dynamic environment, the demand for specialized antiviral compounds, particularly those effective against challenging diseases like Feline Infectious Peritonitis (FIP), has surged. This creates a significant market opportunity for gs-441524 for white liquid type factories. These specialized manufacturing facilities are at the forefront of producing high-purity active pharmaceutical ingredients (APIs) and intermediates, catering to the exacting standards of the pharmaceutical industry.

Current industry trends indicate a strong move towards enhanced supply chain transparency, stringent quality control, and the ability to scale production rapidly to meet demand fluctuations. For manufacturers of complex organic compounds like GS-441524, this translates into an imperative for advanced synthetic capabilities, robust analytical validation, and a commitment to regulatory compliance. The "white liquid type" designation often refers to the highly purified, often concentrated solution of the API or its precursor, ready for further formulation by other veterinary pharmaceutical manufacturers or suppliers. This intermediate form simplifies logistics and ensures consistent quality for end-product developers.

Furthermore, there is a growing emphasis on sustainable manufacturing practices and cost-effective production methods without compromising product integrity. Factories specializing in GS-441524 for white liquid type and gs-441524 for white pill factories must adopt innovative process chemistry and engineering solutions to achieve these objectives, maintaining a competitive edge in a highly specialized global market. The rise of new FIP treatments also highlights the need for continuous research and development in API synthesis to support these emerging therapies.

Detailed Process Flow: Manufacturing GS-441524 White Liquid Type

The manufacturing process for high-purity GS-441524 in its white liquid type is a complex multi-step organic synthesis, demanding precise control over reaction conditions, reagent quality, and purification protocols. Adherence to cGMP (current Good Manufacturing Practices) is paramount throughout the entire production lifecycle, ensuring product consistency, safety, and efficacy.

Key Stages of Synthesis:

- 1. Raw Material Sourcing & Qualification: Starting materials, including ribose derivatives, purine bases, and various reagents, are sourced from qualified suppliers. Each batch undergoes rigorous incoming inspection, verifying identity, purity, and absence of contaminants according to internal specifications and pharmacopoeial standards (e.g., USP, EP). This includes advanced analytical techniques like HPLC, GC-MS, and NMR.

- 2. Multi-Step Organic Synthesis: The synthesis of GS-441524 typically involves several key reaction steps, including glycosylation, amination, and cyclization reactions. These steps are performed in jacketed glass-lined or stainless steel reactors, controlled for temperature, pressure, agitation, and inert atmosphere.

- Glycosylation: Formation of the nucleoside bond between the ribose sugar and the purine base.

- Protection/Deprotection: Strategic use of protecting groups to selectively functionalize reactive sites, followed by their removal to yield the desired structure.

- Functional Group Transformations: Introduction of specific groups required for the final API structure.

Each intermediate product is isolated and purified, often through techniques like crystallization, filtration, and solvent extraction, before proceeding to the next step. In-process controls (IPCs) are conducted at critical junctures to monitor reaction completion, impurity profiles, and yield.

- 3. Purification and Isolation: The crude GS-441524 synthesized from the final reaction step undergoes extensive purification to achieve pharmaceutical-grade purity. Common methods include:

- Recrystallization: Multiple stages using carefully selected solvent systems.

- Chromatography: Preparative HPLC or flash chromatography for fine purification, removing trace impurities and isomeric by-products.

- Filtration: Sterilizing filtration for the liquid type formulation, ensuring microbial control.

- 4. Formulation into White Liquid Type: The purified GS-441524 API is then dissolved in a precisely formulated solvent system (e.g., a mixture of sterile water, ethanol, and co-solvents) to create the stable, homogeneous "white liquid type." This process involves:

- Dissolution: Under controlled temperature and agitation.

- pH Adjustment: To optimize stability and solubility.

- Sterile Filtration: Through 0.22-micron filters to remove particulates and microorganisms.

- Aseptic Filling: Into pre-sterilized container111s (vials, bottles) in ISO Class 5 cleanroom environments.

- 5. Quality Control and Release: Each batch of the final gs-441524 for white liquid type factory product undergoes comprehensive analytical testing against predetermined specifications.

Testing Standards & Target Industries:

Finished product testing adheres to international pharmacopoeial standards (e.g., USP, EP) and internal quality specifications. Key tests include:

- Purity by HPLC (>99.5%)

- Impurity Profile (related substances, residual solvents)

- Assay (potency)

- pH, Osmolality

- Sterility (USP & EP methods)

- Endotoxin Levels (LAL test)

- Particulate Matter

This high-grade gs-441524 for white liquid type supplier product primarily targets the veterinary pharmaceutical industry, specifically manufacturers of FIP treatments. It also serves research and development institutions focused on antiviral drug discovery. The product's stability and purity ensure a long service life and reliable performance in subsequent drug formulations.

Advanced bioreactor systems for large-scale synthesis of GS-441524.

Technical Specifications of Pharmaceutical-Grade GS-441524 (White Liquid Type)

Understanding the precise technical specifications of GS-441524 is critical for pharmaceutical developers and formulators. Our product adheres to stringent quality metrics, ensuring optimal performance in the development of veterinary medicines. Below are typical specifications for the gs-441524 for white liquid type manufacturer grade material.

Product Specification Table: GS-441524 (White Liquid Type API Solution)

| Parameter | Spezifikation | Test Method (e.g., USP/EP equivalent) |

|---|---|---|

| Aussehen | Clear, colorless to pale yellow solution, free from visible particulates | Visual Inspection |

| Concentration | 100 mg/mL, 200 mg/mL, or customized | HPLC-UV |

| Purity (GS-441524) | ≥ 99.5% | HPLC, Area Normalization |

| Total Impurities | ≤ 0.5% | HPLC |

| pH (25°C) | 6.0 - 7.5 | Potentiometric |

| Sterility | Sterile (meets USP & EP requirements) | Membrane Filtration Method |

| Bacterial Endotoxins | < 5.0 EU/mg | LAL Test |

| Residual Solvents | Meets ICH Q3C Guidelines (Class 2 & 3) | GC-HS |

| Storage Conditions | 2-8°C, protected from light | Stability Study Data |

| Shelf Life | 24 months (under recommended storage) | Accelerated & Real-time Stability Studies |

These specifications ensure that the GS-441524 supplied by our white liquid type factories is suitable for direct integration into pharmaceutical formulations, minimizing further purification steps and accelerating product development cycles for our B2B clients, including gs-441524 for white liquid type suppliers and gs-441524 for white liquid type manufacturers globally. The high purity and controlled pH are crucial for maintaining the stability and bioavailability of the final veterinary drug product.

State-of-the-art analytical instrumentation for robust quality control.

Application Scenarios and Technical Advantages

The high-purity GS-441524 in a sterile white liquid type offers significant advantages and diverse application scenarios for veterinary pharmaceutical companies. Its ready-to-use liquid form streamlines downstream processing, reducing complexity and potential for contamination.

Typical Application Scenarios:

- Injectable FIP Formulations: The primary application is as a key API for the manufacturing of injectable solutions used in the treatment of Feline Infectious Peritonitis. The sterile liquid form provided by our gs-441524 for white liquid type factories ensures compliance with parenteral drug standards.

- Oral Solution Development: While often associated with injectables, some veterinary formulations of GS-441524 are developed as oral solutions. Our liquid API facilitates easy integration into palatable oral dosage forms for feline patients.

- Compounding Pharmacies and Specialty Veterinary Clinics: For situations requiring customized dosages or specific excipient profiles, the liquid GS-441524 serves as a reliable base for compounding pharmacists to prepare tailor-made treatments.

- Research and Clinical Trials: Academic institutions and pharmaceutical R&D departments utilize this high-quality API for preclinical studies, pharmacokinetic evaluations, and the development of next-generation antiviral therapies.

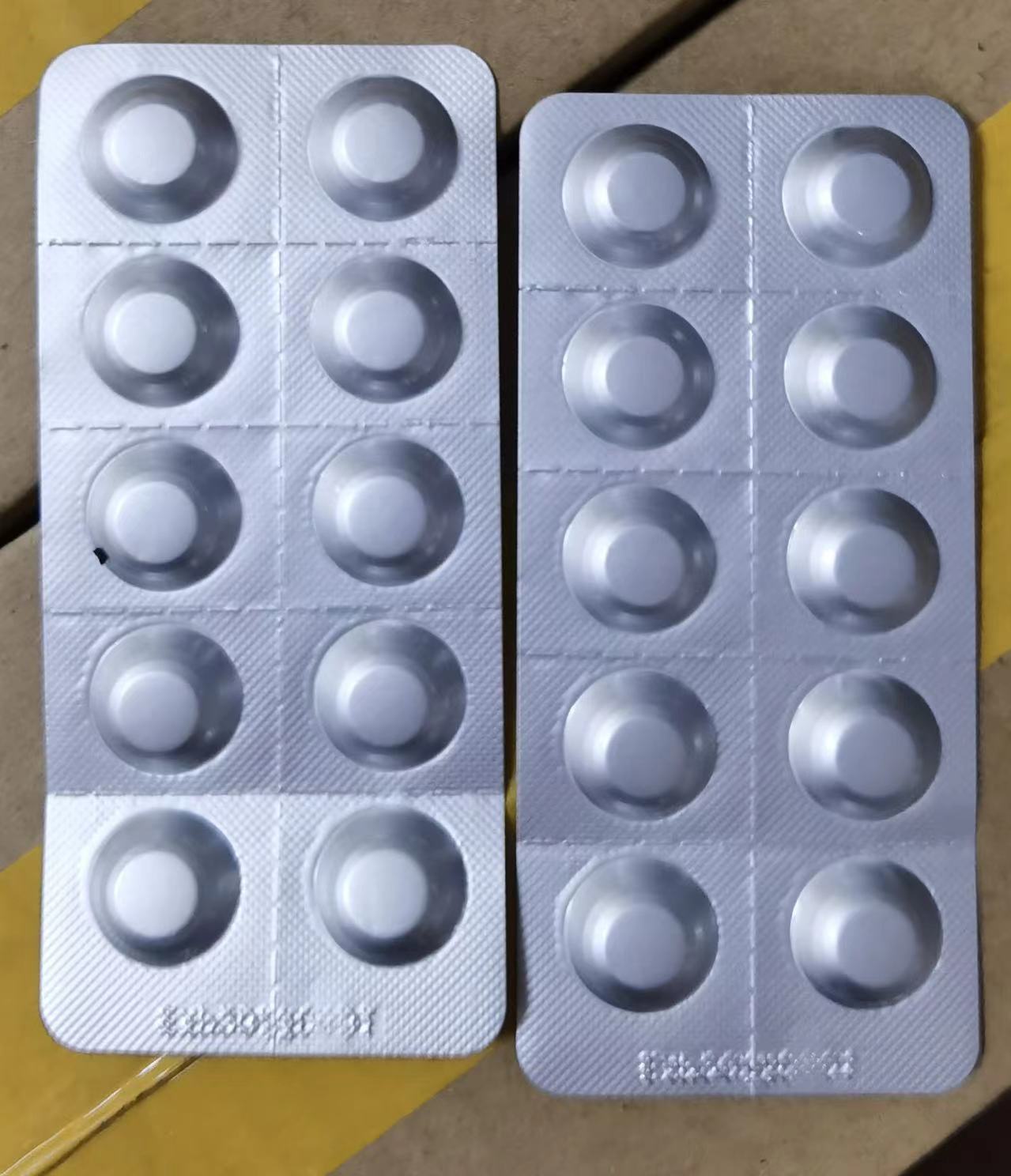

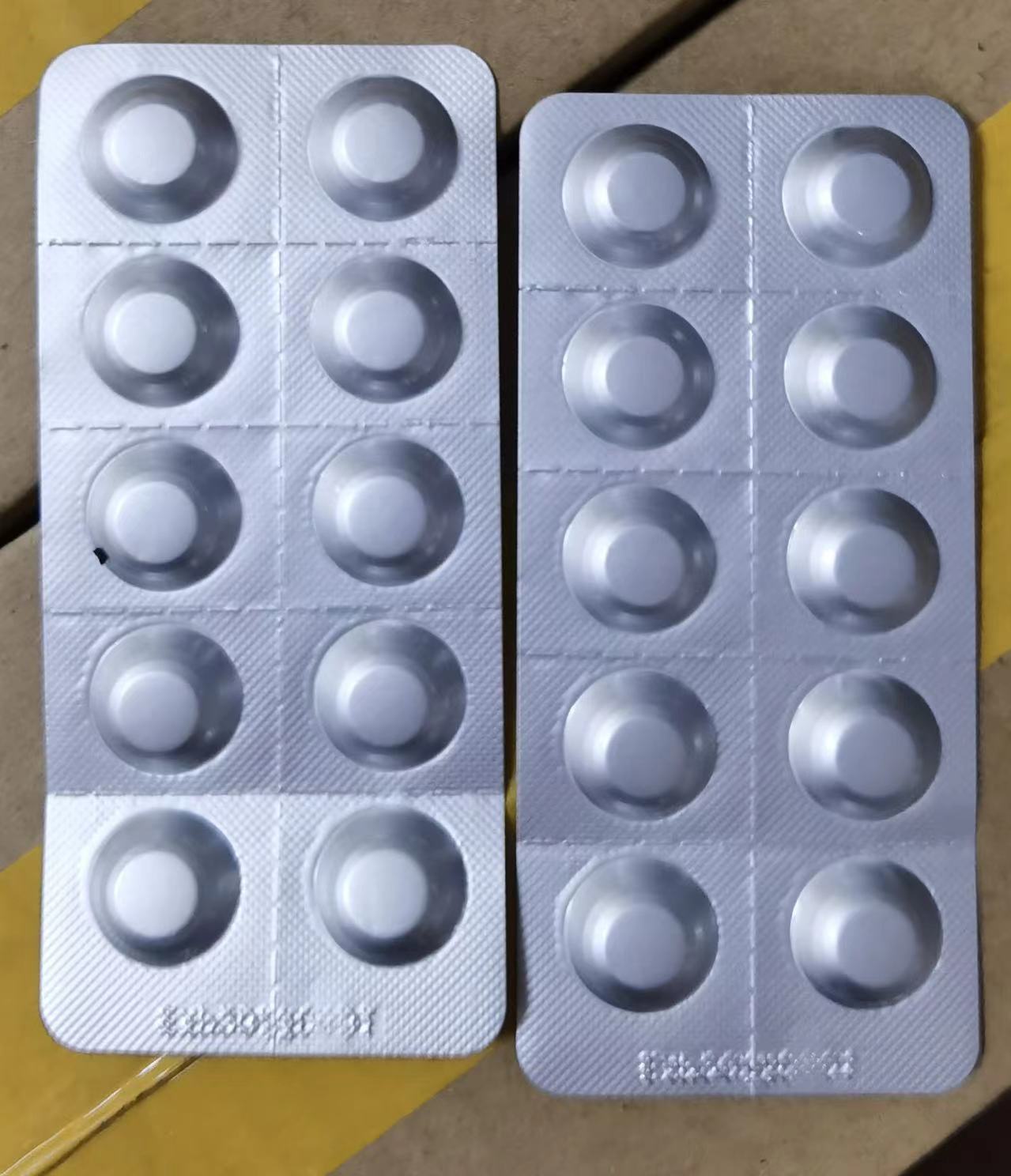

- Production of White Pill Formulations: Although supplied as a liquid, our manufacturing capabilities also support gs-441524 for white pill factories by providing the API in a highly purified solid state, suitable for tableting or capsule filling.

Technical Advantages of Our White Liquid Type GS-441524:

- Enhanced Bioavailability: Our specialized formulations ensure optimal solubility and stability, crucial for effective systemic absorption of the drug in the target animal.

- Reduced Manufacturing Complexity: By providing GS-441524 as a pre-dissolved, sterile liquid, we significantly reduce the need for clients to perform complex dissolution, filtration, and sterilization steps, lowering manufacturing costs and lead times.

- Superior Purity and Consistency: Our multi-stage purification protocols, including advanced chromatography, eliminate impurities that could compromise drug efficacy or safety. Each batch from our gs-441524 for white liquid type factory undergoes stringent analytical validation.

- Compliance with Global Standards: Produced under cGMP guidelines, our GS-441524 meets or exceeds regulatory requirements set by agencies like FDA and EMA for veterinary APIs, facilitating easier product registration for our clients.

- Optimized Stability Profile: The white liquid type is formulated to offer excellent long-term stability under recommended storage conditions, minimizing degradation and ensuring prolonged shelf life for finished products.

- Scalability: Our production infrastructure is designed for seamless scalability, enabling us to consistently supply from small pilot batches to large commercial volumes, supporting the growth of our partners.

Aseptic filling line for pharmaceutical-grade GS-441524 liquid solutions.

Vendor Comparison: Choosing the Right GS-441524 Supplier

Selecting a reliable supplier for critical APIs like GS-441524 is a strategic decision for any pharmaceutical company. A thorough vendor comparison must consider not just price, but also quality, reliability, regulatory compliance, and capacity for customization. Our approach positions us as a premier gs-441524 for white liquid type supplier.

Key Comparison Factors for GS-441524 Manufacturers:

| Feature | Our Offering | Typical Competitor |

|---|---|---|

| Purity of API | ≥ 99.5% (HPLC validated) | Often < 99%, or inconsistent |

| Formulation Type | Sterile White Liquid Type (various concentrations) and Powder | Often only raw powder, requiring extensive client processing |

| Manufacturing Standards | Strict cGMP, ISO 9001, FDA-compliant facilities | Variable, sometimes non-cGMP or basic ISO |

| Batch Consistency | High (demonstrated by COAs & stability data) | Potentially inconsistent due to varied processes |

| Documentation & Support | Full regulatory dossier, DMF support, dedicated technical assistance | Limited documentation, less technical support |

| Customization Capabilities | Yes (concentration, packaging, solvent system) | Rarely, standard products only |

| Supply Chain Security | Robust, multi-source raw materials, disaster recovery plan | Single-source dependent, vulnerable to disruptions |

Our commitment to these factors positions us as a trusted partner for veterinary pharmaceutical product development. We prioritize transparency, rigorous quality assurance, and responsive customer service to ensure a seamless supply chain for our B2B partners, including gs-441524 for white pill suppliers.

Customized Solutions and Application Case Studies

Recognizing the diverse needs of pharmaceutical manufacturers, our gs-441524 for white liquid type factory offers a range of customized solutions. This flexibility ensures that our partners receive an API product perfectly tailored to their specific formulation and regulatory requirements.

Customization Options:

- Concentration Adjustments: We can provide GS-441524 in various concentrations (e.g., 50 mg/mL, 150 mg/mL, 250 mg/mL) to optimize formulation volume and reduce excipient costs for our clients.

- Solvent System Modifications: While our standard liquid type uses a proven safe and effective solvent blend, we can explore custom solvent systems to meet unique solubility or compatibility demands of specific drug products, ensuring stability and injectability.

- Packaging Customization: From bulk drums to pre-filled sterile vials of various sizes (e.g., 10mL, 20mL, 50mL), our packaging solutions can be adapted to integrate seamlessly into client’s manufacturing lines, reducing handling and transfer risks.

- Formulation Assistance: Our R&D team offers collaborative support, advising on excipient selection and formulation strategies to maximize drug stability, bioavailability, and patient compliance for the final product.

Application Case Studies:

Case Study 1: Accelerating FIP Treatment Market Entry

A mid-sized veterinary pharmaceutical company aimed to quickly launch an injectable FIP treatment. They partnered with our gs-441524 for white liquid type manufacturer to source the API. By utilizing our pre-dissolved, sterile GS-441524 at 100 mg/mL, the client significantly reduced their development timeline. They avoided the complexities of API dissolution and sterile filtration, cutting production costs by an estimated 15% and reducing their time-to-market by 4 months. The consistent quality and ready-to-use format allowed them to focus solely on final formulation and regulatory submissions, resulting in a successful market launch and strong initial sales.

Case Study 2: Enhancing Production Efficiency for Oral Formulations

A specialty veterinary compounding pharmacy sought to improve the consistency and shelf-life of their customized oral GS-441524 solutions. Traditional methods involved dissolving raw powder, which often led to variability. By transitioning to our gs-441524 for white liquid type factory's high-concentration liquid, the pharmacy achieved batch-to-batch consistency in potency and appearance. This switch streamlined their compounding process, minimized material waste, and extended the stability of their oral preparations, leading to higher customer satisfaction and repeat business.

Case Study 3: Global Supply Chain Reliability for White Pill Factories

A large multinational veterinary company, operating gs-441524 for white pill factories across multiple continents, faced challenges with securing a consistent supply of high-purity GS-441524 powder. Our robust supply chain and dual manufacturing sites (one focused on liquid, another on solid API) provided the necessary redundancy. We supplied pharmaceutical-grade GS-441524 powder, packaged in specific bulk quantities, directly to their tablet manufacturing facilities. This partnership ensured uninterrupted production, even amidst global logistical challenges, underscoring our capability as a reliable gs-441524 for white pill supplier.

Dedicated R&D efforts support continuous improvement in GS-441524 synthesis and formulation.

Trustworthiness: FAQ, Lead Time, Warranty, and Customer Support

Building trust with our B2B partners is fundamental to our operations as a leading gs-441524 for white liquid type manufacturer. We achieve this through transparent processes, clear communication, and unwavering commitment to post-sales support.

Frequently Asked Questions (FAQ):

- Q: What is the minimum order quantity (MOQ) for GS-441524 white liquid type?

A: Our standard MOQ for white liquid type GS-441524 typically starts from 1 liter, containing 100g of API, but can be flexible for R&D projects or initial trial orders. Please contact our sales team for specific requirements. - Q: Do you provide regulatory documentation such as DMFs (Drug Master Files)?

A: Yes, we provide comprehensive documentation, including Certificates of Analysis (CoA), Material Safety Data Sheets (MSDS), and support with regulatory filings such as Drug Master Files (DMFs) for our pharmaceutical-grade GS-441524, facilitating your product registration process. - Q: Can you customize the concentration or solvent system for the liquid GS-441524?

A: Absolutely. We offer significant flexibility for customization regarding concentration and solvent systems to align with your specific formulation needs. Our technical team works closely with clients to develop tailored solutions. - Q: What are your quality assurance certifications?

A: Our facilities operate under strict cGMP guidelines and are ISO 9001 certified. We adhere to pharmacopoeial standards (USP, EP) and are regularly audited by third parties and our major pharmaceutical clients.

Lead Time and Fulfillment:

We maintain robust inventory levels of key intermediates and have optimized our production scheduling to ensure efficient fulfillment. Standard lead times for commercial quantities of gs-441524 for white liquid type factories material are typically 2-4 weeks from order confirmation, depending on volume and specific customization requirements. Expedited options may be available upon request. Our global logistics network ensures secure and timely delivery to your facilities, complete with cold chain management where necessary.

Warranty Commitments:

All our GS-441524 white liquid type products are guaranteed to meet the specifications detailed in our Certificate of Analysis (CoA) and agreed-upon supply agreements. We warrant that our products are manufactured, stored, and shipped in accordance with cGMP standards and are free from defects in material and workmanship at the time of delivery. Any claims for non-conformance must be reported within a specified period post-receipt, and we commit to thorough investigation and resolution.

Dedicated Customer Support:

Our commitment extends beyond product delivery. We provide dedicated technical support from experienced chemists and regulatory specialists to assist with formulation challenges, analytical method transfers, and regulatory queries. Our customer service team is available during business hours to address any logistical or order-related concerns promptly. We believe in fostering long-term partnerships built on trust, reliability, and mutual success. For immediate assistance, please visit our product URL or contact our support channels directly.

Authoritative References and Certifications

Our operations and product quality are underpinned by adherence to globally recognized standards and extensive certifications, reinforcing our position as an authoritative and reliable source for GS-441524. We are committed to transparency and providing robust evidence of our compliance and capabilities.

Certifications and Compliance:

- cGMP Compliance: Our manufacturing facilities strictly follow current Good Manufacturing Practices (cGMP) as mandated by leading pharmaceutical regulatory bodies. This ensures that our GS-441524 is produced under conditions that prevent contamination and ensure consistent quality.

- ISO 9001:2015 Certified: Our Quality Management System (QMS) is certified to ISO 9001:2015, demonstrating our commitment to continuous improvement and customer satisfaction across all processes.

- Pharmacopoeial Adherence: Our testing and release criteria align with major pharmacopoeial standards, including the United States Pharmacopeia (USP) and the European Pharmacopoeia (EP), where applicable for API quality.

- FDA/ICH Guidelines: We operate in accordance with FDA guidelines for pharmaceutical raw materials and intermediates, and our impurity profiles are managed per ICH Q3A/B/C guidelines for drug substances and residual solvents.

Partners and Years of Service:

With over a decade of experience in specialized chemical synthesis and pharmaceutical intermediate supply, we have forged strong partnerships with leading veterinary pharmaceutical companies and research institutions worldwide. Our long-standing client relationships are a testament to our consistent quality and reliable service as a trusted gs-441524 for white liquid type factory.

Verweise

- USP – United States Pharmacopeia. General Chapters. "Good Manufacturing Practices".

- ICH Harmonised Tripartite Guideline. Q7: Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients.

- European Medicines Agency. Guidance for active substance manufacturers.

- Perrin, M. R., Kipar, A., & Knaus, U. (2020). Feline infectious peritonitis: a review of the latest advances in diagnostics and treatments. Veterinary Record, 187(11), 444.

- Murphy, B. G., & et al. (2018). The nucleoside analog GS-441524 is a highly effective treatment for feline infectious peritonitis (FIP) in cats. Journal of Veterinary Internal Medicine, 32(5), 1629-1631.

-

CAS: 79099-07-3 Factories | GMP Stock, OEM, Fast Delivery

NachrichtNov.17,2025

-

CAS: 79099-07-3 Factories | GMP Quality, Factory Prices

NachrichtNov.17,2025

-

GS-441524 for White Liquid Type Factories | GMP OEM Bulk

NachrichtNov.17,2025

-

CAS: 79099-07-3 Factories | GMP Bulk Supply, Fast Shipping

NachrichtNov.17,2025

-

gs-441524 for white liquid type factories | GMP & fast ship

NachrichtNov.17,2025

-

High-Purity cas 1451-83-8 factory | GMP Bulk, Fast Delivery

NachrichtNov.17,2025

Sep . 08, 2025 16:38 Zurück zur Liste

Premium GS-441524 for White Liquid Type Factories - Purity Assured

Industry Trends and the Evolving Landscape for GS-441524 Production

The global veterinary pharmaceutical market is experiencing robust growth, driven by increasing pet ownership, advancements in animal healthcare, and a heightened focus on companion animal well-being. Within this dynamic environment, the demand for specialized antiviral compounds, particularly those effective against challenging diseases like Feline Infectious Peritonitis (FIP), has surged. This creates a significant market opportunity for gs-441524 for white liquid type factories. These specialized manufacturing facilities are at the forefront of producing high-purity active pharmaceutical ingredients (APIs) and intermediates, catering to the exacting standards of the pharmaceutical industry.

Current industry trends indicate a strong move towards enhanced supply chain transparency, stringent quality control, and the ability to scale production rapidly to meet demand fluctuations. For manufacturers of complex organic compounds like GS-441524, this translates into an imperative for advanced synthetic capabilities, robust analytical validation, and a commitment to regulatory compliance. The "white liquid type" designation often refers to the highly purified, often concentrated solution of the API or its precursor, ready for further formulation by other veterinary pharmaceutical manufacturers or suppliers. This intermediate form simplifies logistics and ensures consistent quality for end-product developers.

Furthermore, there is a growing emphasis on sustainable manufacturing practices and cost-effective production methods without compromising product integrity. Factories specializing in GS-441524 for white liquid type and gs-441524 for white pill factories must adopt innovative process chemistry and engineering solutions to achieve these objectives, maintaining a competitive edge in a highly specialized global market. The rise of new FIP treatments also highlights the need for continuous research and development in API synthesis to support these emerging therapies.

Detailed Process Flow: Manufacturing GS-441524 White Liquid Type

The manufacturing process for high-purity GS-441524 in its white liquid type is a complex multi-step organic synthesis, demanding precise control over reaction conditions, reagent quality, and purification protocols. Adherence to cGMP (current Good Manufacturing Practices) is paramount throughout the entire production lifecycle, ensuring product consistency, safety, and efficacy.

Key Stages of Synthesis:

- 1. Raw Material Sourcing & Qualification: Starting materials, including ribose derivatives, purine bases, and various reagents, are sourced from qualified suppliers. Each batch undergoes rigorous incoming inspection, verifying identity, purity, and absence of contaminants according to internal specifications and pharmacopoeial standards (e.g., USP, EP). This includes advanced analytical techniques like HPLC, GC-MS, and NMR.

- 2. Multi-Step Organic Synthesis: The synthesis of GS-441524 typically involves several key reaction steps, including glycosylation, amination, and cyclization reactions. These steps are performed in jacketed glass-lined or stainless steel reactors, controlled for temperature, pressure, agitation, and inert atmosphere.

- Glycosylation: Formation of the nucleoside bond between the ribose sugar and the purine base.

- Protection/Deprotection: Strategic use of protecting groups to selectively functionalize reactive sites, followed by their removal to yield the desired structure.

- Functional Group Transformations: Introduction of specific groups required for the final API structure.

Each intermediate product is isolated and purified, often through techniques like crystallization, filtration, and solvent extraction, before proceeding to the next step. In-process controls (IPCs) are conducted at critical junctures to monitor reaction completion, impurity profiles, and yield.

- 3. Purification and Isolation: The crude GS-441524 synthesized from the final reaction step undergoes extensive purification to achieve pharmaceutical-grade purity. Common methods include:

- Recrystallization: Multiple stages using carefully selected solvent systems.

- Chromatography: Preparative HPLC or flash chromatography for fine purification, removing trace impurities and isomeric by-products.

- Filtration: Sterilizing filtration for the liquid type formulation, ensuring microbial control.

- 4. Formulation into White Liquid Type: The purified GS-441524 API is then dissolved in a precisely formulated solvent system (e.g., a mixture of sterile water, ethanol, and co-solvents) to create the stable, homogeneous "white liquid type." This process involves:

- Dissolution: Under controlled temperature and agitation.

- pH Adjustment: To optimize stability and solubility.

- Sterile Filtration: Through 0.22-micron filters to remove particulates and microorganisms.

- Aseptic Filling: Into pre-sterilized container111s (vials, bottles) in ISO Class 5 cleanroom environments.

- 5. Quality Control and Release: Each batch of the final gs-441524 for white liquid type factory product undergoes comprehensive analytical testing against predetermined specifications.

Testing Standards & Target Industries:

Finished product testing adheres to international pharmacopoeial standards (e.g., USP, EP) and internal quality specifications. Key tests include:

- Purity by HPLC (>99.5%)

- Impurity Profile (related substances, residual solvents)

- Assay (potency)

- pH, Osmolality

- Sterility (USP & EP methods)

- Endotoxin Levels (LAL test)

- Particulate Matter

This high-grade gs-441524 for white liquid type supplier product primarily targets the veterinary pharmaceutical industry, specifically manufacturers of FIP treatments. It also serves research and development institutions focused on antiviral drug discovery. The product's stability and purity ensure a long service life and reliable performance in subsequent drug formulations.

Advanced bioreactor systems for large-scale synthesis of GS-441524.

Technical Specifications of Pharmaceutical-Grade GS-441524 (White Liquid Type)

Understanding the precise technical specifications of GS-441524 is critical for pharmaceutical developers and formulators. Our product adheres to stringent quality metrics, ensuring optimal performance in the development of veterinary medicines. Below are typical specifications for the gs-441524 for white liquid type manufacturer grade material.

Product Specification Table: GS-441524 (White Liquid Type API Solution)

| Parameter | Spezifikation | Test Method (e.g., USP/EP equivalent) |

|---|---|---|

| Aussehen | Clear, colorless to pale yellow solution, free from visible particulates | Visual Inspection |

| Concentration | 100 mg/mL, 200 mg/mL, or customized | HPLC-UV |

| Purity (GS-441524) | ≥ 99.5% | HPLC, Area Normalization |

| Total Impurities | ≤ 0.5% | HPLC |

| pH (25°C) | 6.0 - 7.5 | Potentiometric |

| Sterility | Sterile (meets USP & EP requirements) | Membrane Filtration Method |

| Bacterial Endotoxins | < 5.0 EU/mg | LAL Test |

| Residual Solvents | Meets ICH Q3C Guidelines (Class 2 & 3) | GC-HS |

| Storage Conditions | 2-8°C, protected from light | Stability Study Data |

| Shelf Life | 24 months (under recommended storage) | Accelerated & Real-time Stability Studies |

These specifications ensure that the GS-441524 supplied by our white liquid type factories is suitable for direct integration into pharmaceutical formulations, minimizing further purification steps and accelerating product development cycles for our B2B clients, including gs-441524 for white liquid type suppliers and gs-441524 for white liquid type manufacturers globally. The high purity and controlled pH are crucial for maintaining the stability and bioavailability of the final veterinary drug product.

State-of-the-art analytical instrumentation for robust quality control.

Application Scenarios and Technical Advantages

The high-purity GS-441524 in a sterile white liquid type offers significant advantages and diverse application scenarios for veterinary pharmaceutical companies. Its ready-to-use liquid form streamlines downstream processing, reducing complexity and potential for contamination.

Typical Application Scenarios:

- Injectable FIP Formulations: The primary application is as a key API for the manufacturing of injectable solutions used in the treatment of Feline Infectious Peritonitis. The sterile liquid form provided by our gs-441524 for white liquid type factories ensures compliance with parenteral drug standards.

- Oral Solution Development: While often associated with injectables, some veterinary formulations of GS-441524 are developed as oral solutions. Our liquid API facilitates easy integration into palatable oral dosage forms for feline patients.

- Compounding Pharmacies and Specialty Veterinary Clinics: For situations requiring customized dosages or specific excipient profiles, the liquid GS-441524 serves as a reliable base for compounding pharmacists to prepare tailor-made treatments.

- Research and Clinical Trials: Academic institutions and pharmaceutical R&D departments utilize this high-quality API for preclinical studies, pharmacokinetic evaluations, and the development of next-generation antiviral therapies.

- Production of White Pill Formulations: Although supplied as a liquid, our manufacturing capabilities also support gs-441524 for white pill factories by providing the API in a highly purified solid state, suitable for tableting or capsule filling.

Technical Advantages of Our White Liquid Type GS-441524:

- Enhanced Bioavailability: Our specialized formulations ensure optimal solubility and stability, crucial for effective systemic absorption of the drug in the target animal.

- Reduced Manufacturing Complexity: By providing GS-441524 as a pre-dissolved, sterile liquid, we significantly reduce the need for clients to perform complex dissolution, filtration, and sterilization steps, lowering manufacturing costs and lead times.

- Superior Purity and Consistency: Our multi-stage purification protocols, including advanced chromatography, eliminate impurities that could compromise drug efficacy or safety. Each batch from our gs-441524 for white liquid type factory undergoes stringent analytical validation.

- Compliance with Global Standards: Produced under cGMP guidelines, our GS-441524 meets or exceeds regulatory requirements set by agencies like FDA and EMA for veterinary APIs, facilitating easier product registration for our clients.

- Optimized Stability Profile: The white liquid type is formulated to offer excellent long-term stability under recommended storage conditions, minimizing degradation and ensuring prolonged shelf life for finished products.

- Scalability: Our production infrastructure is designed for seamless scalability, enabling us to consistently supply from small pilot batches to large commercial volumes, supporting the growth of our partners.

Aseptic filling line for pharmaceutical-grade GS-441524 liquid solutions.

Vendor Comparison: Choosing the Right GS-441524 Supplier

Selecting a reliable supplier for critical APIs like GS-441524 is a strategic decision for any pharmaceutical company. A thorough vendor comparison must consider not just price, but also quality, reliability, regulatory compliance, and capacity for customization. Our approach positions us as a premier gs-441524 for white liquid type supplier.

Key Comparison Factors for GS-441524 Manufacturers:

| Feature | Our Offering | Typical Competitor |

|---|---|---|

| Purity of API | ≥ 99.5% (HPLC validated) | Often < 99%, or inconsistent |

| Formulation Type | Sterile White Liquid Type (various concentrations) and Powder | Often only raw powder, requiring extensive client processing |

| Manufacturing Standards | Strict cGMP, ISO 9001, FDA-compliant facilities | Variable, sometimes non-cGMP or basic ISO |

| Batch Consistency | High (demonstrated by COAs & stability data) | Potentially inconsistent due to varied processes |

| Documentation & Support | Full regulatory dossier, DMF support, dedicated technical assistance | Limited documentation, less technical support |

| Customization Capabilities | Yes (concentration, packaging, solvent system) | Rarely, standard products only |

| Supply Chain Security | Robust, multi-source raw materials, disaster recovery plan | Single-source dependent, vulnerable to disruptions |

Our commitment to these factors positions us as a trusted partner for veterinary pharmaceutical product development. We prioritize transparency, rigorous quality assurance, and responsive customer service to ensure a seamless supply chain for our B2B partners, including gs-441524 for white pill suppliers.

Customized Solutions and Application Case Studies

Recognizing the diverse needs of pharmaceutical manufacturers, our gs-441524 for white liquid type factory offers a range of customized solutions. This flexibility ensures that our partners receive an API product perfectly tailored to their specific formulation and regulatory requirements.

Customization Options:

- Concentration Adjustments: We can provide GS-441524 in various concentrations (e.g., 50 mg/mL, 150 mg/mL, 250 mg/mL) to optimize formulation volume and reduce excipient costs for our clients.

- Solvent System Modifications: While our standard liquid type uses a proven safe and effective solvent blend, we can explore custom solvent systems to meet unique solubility or compatibility demands of specific drug products, ensuring stability and injectability.

- Packaging Customization: From bulk drums to pre-filled sterile vials of various sizes (e.g., 10mL, 20mL, 50mL), our packaging solutions can be adapted to integrate seamlessly into client’s manufacturing lines, reducing handling and transfer risks.

- Formulation Assistance: Our R&D team offers collaborative support, advising on excipient selection and formulation strategies to maximize drug stability, bioavailability, and patient compliance for the final product.

Application Case Studies:

Case Study 1: Accelerating FIP Treatment Market Entry

A mid-sized veterinary pharmaceutical company aimed to quickly launch an injectable FIP treatment. They partnered with our gs-441524 for white liquid type manufacturer to source the API. By utilizing our pre-dissolved, sterile GS-441524 at 100 mg/mL, the client significantly reduced their development timeline. They avoided the complexities of API dissolution and sterile filtration, cutting production costs by an estimated 15% and reducing their time-to-market by 4 months. The consistent quality and ready-to-use format allowed them to focus solely on final formulation and regulatory submissions, resulting in a successful market launch and strong initial sales.

Case Study 2: Enhancing Production Efficiency for Oral Formulations

A specialty veterinary compounding pharmacy sought to improve the consistency and shelf-life of their customized oral GS-441524 solutions. Traditional methods involved dissolving raw powder, which often led to variability. By transitioning to our gs-441524 for white liquid type factory's high-concentration liquid, the pharmacy achieved batch-to-batch consistency in potency and appearance. This switch streamlined their compounding process, minimized material waste, and extended the stability of their oral preparations, leading to higher customer satisfaction and repeat business.

Case Study 3: Global Supply Chain Reliability for White Pill Factories

A large multinational veterinary company, operating gs-441524 for white pill factories across multiple continents, faced challenges with securing a consistent supply of high-purity GS-441524 powder. Our robust supply chain and dual manufacturing sites (one focused on liquid, another on solid API) provided the necessary redundancy. We supplied pharmaceutical-grade GS-441524 powder, packaged in specific bulk quantities, directly to their tablet manufacturing facilities. This partnership ensured uninterrupted production, even amidst global logistical challenges, underscoring our capability as a reliable gs-441524 for white pill supplier.

Dedicated R&D efforts support continuous improvement in GS-441524 synthesis and formulation.

Trustworthiness: FAQ, Lead Time, Warranty, and Customer Support

Building trust with our B2B partners is fundamental to our operations as a leading gs-441524 for white liquid type manufacturer. We achieve this through transparent processes, clear communication, and unwavering commitment to post-sales support.

Frequently Asked Questions (FAQ):

- Q: What is the minimum order quantity (MOQ) for GS-441524 white liquid type?

A: Our standard MOQ for white liquid type GS-441524 typically starts from 1 liter, containing 100g of API, but can be flexible for R&D projects or initial trial orders. Please contact our sales team for specific requirements. - Q: Do you provide regulatory documentation such as DMFs (Drug Master Files)?

A: Yes, we provide comprehensive documentation, including Certificates of Analysis (CoA), Material Safety Data Sheets (MSDS), and support with regulatory filings such as Drug Master Files (DMFs) for our pharmaceutical-grade GS-441524, facilitating your product registration process. - Q: Can you customize the concentration or solvent system for the liquid GS-441524?

A: Absolutely. We offer significant flexibility for customization regarding concentration and solvent systems to align with your specific formulation needs. Our technical team works closely with clients to develop tailored solutions. - Q: What are your quality assurance certifications?

A: Our facilities operate under strict cGMP guidelines and are ISO 9001 certified. We adhere to pharmacopoeial standards (USP, EP) and are regularly audited by third parties and our major pharmaceutical clients.

Lead Time and Fulfillment:

We maintain robust inventory levels of key intermediates and have optimized our production scheduling to ensure efficient fulfillment. Standard lead times for commercial quantities of gs-441524 for white liquid type factories material are typically 2-4 weeks from order confirmation, depending on volume and specific customization requirements. Expedited options may be available upon request. Our global logistics network ensures secure and timely delivery to your facilities, complete with cold chain management where necessary.

Warranty Commitments:

All our GS-441524 white liquid type products are guaranteed to meet the specifications detailed in our Certificate of Analysis (CoA) and agreed-upon supply agreements. We warrant that our products are manufactured, stored, and shipped in accordance with cGMP standards and are free from defects in material and workmanship at the time of delivery. Any claims for non-conformance must be reported within a specified period post-receipt, and we commit to thorough investigation and resolution.

Dedicated Customer Support:

Our commitment extends beyond product delivery. We provide dedicated technical support from experienced chemists and regulatory specialists to assist with formulation challenges, analytical method transfers, and regulatory queries. Our customer service team is available during business hours to address any logistical or order-related concerns promptly. We believe in fostering long-term partnerships built on trust, reliability, and mutual success. For immediate assistance, please visit our product URL or contact our support channels directly.

Authoritative References and Certifications

Our operations and product quality are underpinned by adherence to globally recognized standards and extensive certifications, reinforcing our position as an authoritative and reliable source for GS-441524. We are committed to transparency and providing robust evidence of our compliance and capabilities.

Certifications and Compliance:

- cGMP Compliance: Our manufacturing facilities strictly follow current Good Manufacturing Practices (cGMP) as mandated by leading pharmaceutical regulatory bodies. This ensures that our GS-441524 is produced under conditions that prevent contamination and ensure consistent quality.

- ISO 9001:2015 Certified: Our Quality Management System (QMS) is certified to ISO 9001:2015, demonstrating our commitment to continuous improvement and customer satisfaction across all processes.

- Pharmacopoeial Adherence: Our testing and release criteria align with major pharmacopoeial standards, including the United States Pharmacopeia (USP) and the European Pharmacopoeia (EP), where applicable for API quality.

- FDA/ICH Guidelines: We operate in accordance with FDA guidelines for pharmaceutical raw materials and intermediates, and our impurity profiles are managed per ICH Q3A/B/C guidelines for drug substances and residual solvents.

Partners and Years of Service:

With over a decade of experience in specialized chemical synthesis and pharmaceutical intermediate supply, we have forged strong partnerships with leading veterinary pharmaceutical companies and research institutions worldwide. Our long-standing client relationships are a testament to our consistent quality and reliable service as a trusted gs-441524 for white liquid type factory.

Verweise

- USP – United States Pharmacopeia. General Chapters. "Good Manufacturing Practices".

- ICH Harmonised Tripartite Guideline. Q7: Good Manufacturing Practice Guide for Active Pharmaceutical Ingredients.

- European Medicines Agency. Guidance for active substance manufacturers.

- Perrin, M. R., Kipar, A., & Knaus, U. (2020). Feline infectious peritonitis: a review of the latest advances in diagnostics and treatments. Veterinary Record, 187(11), 444.

- Murphy, B. G., & et al. (2018). The nucleoside analog GS-441524 is a highly effective treatment for feline infectious peritonitis (FIP) in cats. Journal of Veterinary Internal Medicine, 32(5), 1629-1631.