- +86-13363869198

- weimiaohb@126.com

Dec . 25, 2024 14:35 Back to list

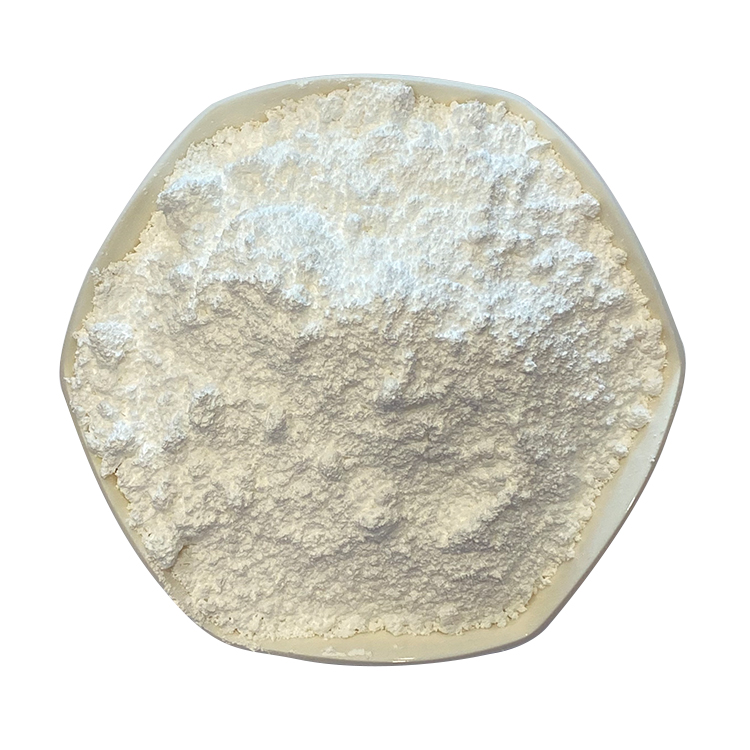

tadalafil cas 171596-29-5 manufacturer

Tadalafil A Comprehensive Overview of Its Manufacturing and Applications

Tadalafil, a medication primarily used to treat erectile dysfunction and pulmonary arterial hypertension, is known by its CAS number 171596-29-5. The drug belongs to a class of compounds known as phosphodiesterase type 5 inhibitors, which work by increasing blood flow to certain areas of the body. Over the years, the demand for tadalafil has surged, consequently prompting a focus on its manufacturing processes and the companies involved in its production.

Understanding Tadalafil

Tadalafil was first approved by the FDA in 2003 under the brand name Cialis. It operates by inhibiting the phosphodiesterase type 5 enzyme, which regulates blood flow in the penis. By blocking this enzyme, tadalafil allows for the relaxation of blood vessels and improved blood flow in the presence of sexual stimulation. Besides its primary use in treating erectile dysfunction, tadalafil is also prescribed for treating benign prostatic hyperplasia and pulmonary arterial hypertension, showcasing its versatility in therapeutic applications.

The Demand for Tadalafil

With the rising incidence of erectile dysfunction globally, the market for tadalafil has expanded significantly. Reports indicate that millions of men are affected by this condition, driving the demand for effective treatment options. Moreover, the increasing awareness of sexual health issues has encouraged more individuals to seek assistance, further fueling the growth of the tadalafil market.

Manufacturing Process of Tadalafil

The manufacturing of tadalafil involves several steps, typically categorized into synthesis, purification, and formulation. The initial synthesis of tadalafil requires several chemical reactions, beginning with the creation of a core chemical structure that is then modified to yield the final product.

The process typically includes

1. Raw Material Sourcing High-quality starting materials are crucial, as they significantly affect the purity and efficacy of the final product.

2. Chemical Synthesis Tadalafil is synthesized through a multi-step chemical process. This usually involves reactions such as cyclization and methylation, which are carefully controlled to avoid impurities.

tadalafil cas 171596-29-5 manufacturer

3. Purification After synthesis, the crude tadalafil undergoes purification. This step is vital to eliminate any byproducts or residual solvents, ensuring the drug meets the required pharmacopoeial standards.

4. Formulation Once purified, tadalafil is then formulated into various acceptable forms, such as tablets or oral suspensions. This step may involve blending the active pharmaceutical ingredient (API) with excipients, which aid in the drug’s stability and absorption.

5. Quality Control Rigorous quality control tests are performed to ensure that the product meets all safety and efficacy standards before it is released into the market. This includes testing for potency, impurities, and dissolution rates.

Leading Manufacturers

The production of tadalafil is carried out by various pharmaceutical companies around the globe. Prominent manufacturers include both large multinational corporations and specialized generic pharmaceutical companies. Some companies focus on the research and development of innovative formulations of tadalafil, aiming to enhance bioavailability and reduce side effects.

Among the notable manufacturers, several Chinese and Indian companies have gained traction in the generic market, providing competitive pricing and scalability. These manufacturers adhere to Good Manufacturing Practices (GMP) and are often subject to inspections by regulatory authorities like the FDA and EMA.

Regulatory Considerations

Given the significance of tadalafil as a therapeutic drug, stringent regulations govern its production. Manufacturers must comply with local and international guidelines, including obtaining necessary licenses and certifications. Quality assurance throughout the manufacturing process is crucial, as it ensures patient safety and the integrity of the product.

Conclusion

As the demand for tadalafil continues to rise, the importance of efficient and compliant manufacturing processes cannot be overstated. From raw material selection to final product testing, each step in the production chain plays a pivotal role in ensuring the availability of a safe and effective treatment for erectile dysfunction and other related conditions. The landscape of tadalafil manufacturing is characterized by innovation, rigorous regulatory requirements, and the quest for quality, emphasizing the critical role of manufacturers in meeting global health needs.

-

GS-441524 White Liquid Production for Factories | AI-Optimized

NewsAug.02,2025

-

AI-Optimized CAS: 79099-07-3 Factories for High Yield

NewsAug.01,2025

-

Premium CAS 1451-83-8 Factory with GPT-4 Turbo | AI-Optimized

NewsJul.31,2025

-

Pharmaceutical Intermediates - AI-Optimized Synthesis & Purity

NewsJul.31,2025

-

Top CAS: 79099-07-3 Factories & Wholesale Supplier from China

NewsJul.30,2025

-

High-Quality GS-441524 for White Liquid Type Factories & Suppliers

NewsJul.29,2025