- +86-13363869198

- weimiaohb@126.com

Aug . 13, 2024 23:01 Back to list

Exploring Lopinavir Manufacturing Facilities for Optimal Quality and Production Standards in Pharmaceuticals

Lopinavir An Insight into Factories and Production Processes

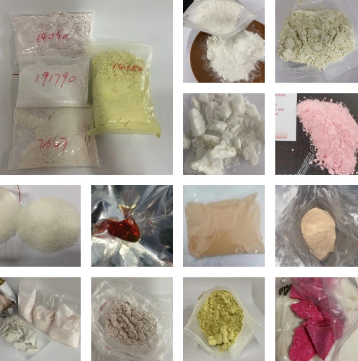

Lopinavir, a medication primarily used in the treatment of HIV/AIDS, is classified as a protease inhibitor. With the CAS number 192725-17-0, this pharmaceutical compound plays a crucial role in antiretroviral therapy, often combined with ritonavir to enhance its efficacy and withstand metabolic breakdown. Understanding the factories involved in its production is essential for a clearer perspective on the pharmaceutical manufacturing landscape and the challenges it encompasses.

The production of lopinavir primarily occurs in specialized pharmaceutical factories designed to meet stringent regulatory standards imposed by health authorities like the FDA and EMA. These facilities are equipped with advanced technology and adhere to Good Manufacturing Practices (GMP), which ensure the safety, quality, and efficacy of medicinal products. Factories involved in the synthesis of lopinavir must establish robust quality control mechanisms throughout the production process to guarantee that each batch meets the required specifications.

Lopinavir An Insight into Factories and Production Processes

Once synthesized, the compound undergoes purification to eliminate any remaining impurities. This step is critical, as the presence of contaminants can significantly affect the drug's safety and effectiveness. Purification methods often involve crystallization, filtration, and other separation techniques that enhance the compound's quality.

lopinavir cas 192725-17-0 factories

Formulation is the final stage before the product is packaged and distributed. Lopinavir is typically formulated into tablets, soft gels, or oral solutions, depending on the intended route of administration. Each formulation must ensure optimal bioavailability and patient compliance, and as such, the excipients used in these formulations are also carefully selected and tested.

In recent years, the global demand for lopinavir surged, particularly during the COVID-19 pandemic, when it was explored as a potential treatment option. This increased demand highlighted some of the vulnerabilities within the pharmaceutical supply chain, including the dependence on a limited number of manufacturers. Such situations can lead to supply shortages, prompting the need for diversified production sources and the establishment of new factories capable of producing essential medications like lopinavir.

Moreover, the ethical considerations surrounding pharmaceutical production cannot be overlooked. Factories must ensure they source their raw materials responsibly and are transparent about their environmental impact. The inclusion of sustainability practices in manufacturing processes is becoming increasingly vital as the world moves towards greener solutions.

In conclusion, the production of lopinavir represents a complex and refined process that highlights the interplay of chemistry, engineering, and regulatory compliance. Factories dedicated to its manufacturing are integral to ensuring a consistent supply of this essential medication. As the global health landscape continues to evolve, ongoing investment in pharmaceutical manufacturing capabilities, along with a focus on sustainability and ethical production, will be crucial in meeting the ever-growing demand for effective antiretroviral therapies. The journey of lopinavir from chemical synthesis to patient administration exemplifies the critical role that modern pharmaceutical factories play in safeguarding public health.

-

GS-441524 for White Liquid Factories: Boost Efficiency & Purity

NewsAug.04,2025

-

Premium Pharma Intermediates | AI-Optimized Synthesis

NewsAug.03,2025

-

GS-441524 White Liquid Production for Factories | AI-Optimized

NewsAug.02,2025

-

AI-Optimized CAS: 79099-07-3 Factories for High Yield

NewsAug.01,2025

-

Premium CAS 1451-83-8 Factory with GPT-4 Turbo | AI-Optimized

NewsJul.31,2025

-

Pharmaceutical Intermediates - AI-Optimized Synthesis & Purity

NewsJul.31,2025