- +86-13363869198

- weimiaohb@126.com

Feb . 19, 2025 11:56 Back to list

100% safe delivery SGT-151 SGT-163 SGT-78 with best price

Dermaseptin, categorized under CAS number 136212-91-4, is a pioneering peptide renowned for its antimicrobial properties. Its effectiveness against a broad spectrum of pathogens has led to increasing interest from pharmaceutical manufacturers and research institutions worldwide. As the demand for this remarkable peptide rises, understanding where and how it is produced becomes crucial for industries aiming to utilize it in healthcare and therapeutic formulations.

In terms of trustworthiness, factories that produce Dermaseptin are transparent in their operations. They often provide comprehensive documentation covering the peptide’s chain of production, from raw materials to finished product. This transparency extends to offering certificates of analysis and batch records which are critical in maintaining consumer trust and securing long-term partnerships. From an experiential standpoint, user testimonials and long-term case studies contribute significantly to understanding the real-world applications and benefits of Dermaseptin. Factories often collaborate with healthcare providers and researchers to gather feedback and refine their products, ensuring Dermaseptin’s applications remain beneficial and innovative. This cyclical feedback loop aids in both product refinement and the solidification of the manufacturer’s reputation. Advanced Dermaseptin factories not only excel in production but also prioritize sustainability and eco-friendly practices. The integration of greener technologies, reduction of waste, and efficient resource management is becoming increasingly vital to align with global sustainability goals. Factories that embrace such initiatives are not only contributing to environmental conservation but also appealing to environmentally-conscious clients. In conclusion, navigating the landscape of Dermaseptin CAS 136212-91-4 production requires careful examination of the factories' capabilities, commitment to quality, and ethical practices. As the peptide’s applications in therapeutics continue to expand, selecting the right producer becomes imperative. Potential clients should leverage the expertise, authority, and trustworthiness of these manufacturers to secure a reliable supply of high-quality Dermaseptin. Such strategic partnerships not only fuel innovation but also ensure the delivery of safe and effective medical solutions to the market.

In terms of trustworthiness, factories that produce Dermaseptin are transparent in their operations. They often provide comprehensive documentation covering the peptide’s chain of production, from raw materials to finished product. This transparency extends to offering certificates of analysis and batch records which are critical in maintaining consumer trust and securing long-term partnerships. From an experiential standpoint, user testimonials and long-term case studies contribute significantly to understanding the real-world applications and benefits of Dermaseptin. Factories often collaborate with healthcare providers and researchers to gather feedback and refine their products, ensuring Dermaseptin’s applications remain beneficial and innovative. This cyclical feedback loop aids in both product refinement and the solidification of the manufacturer’s reputation. Advanced Dermaseptin factories not only excel in production but also prioritize sustainability and eco-friendly practices. The integration of greener technologies, reduction of waste, and efficient resource management is becoming increasingly vital to align with global sustainability goals. Factories that embrace such initiatives are not only contributing to environmental conservation but also appealing to environmentally-conscious clients. In conclusion, navigating the landscape of Dermaseptin CAS 136212-91-4 production requires careful examination of the factories' capabilities, commitment to quality, and ethical practices. As the peptide’s applications in therapeutics continue to expand, selecting the right producer becomes imperative. Potential clients should leverage the expertise, authority, and trustworthiness of these manufacturers to secure a reliable supply of high-quality Dermaseptin. Such strategic partnerships not only fuel innovation but also ensure the delivery of safe and effective medical solutions to the market.

Latest news

-

High-Purity Pharma Intermediates & API | Reliable Supply

NewsAug.26,2025

-

High-Quality Pharma Intermediates | Trusted Manufacturer

NewsAug.25,2025

-

Premium Pharma Intermediates & API | Trusted Global Supplier

NewsAug.24,2025

-

High-Purity cas 1451-83-8 Factory | LGD-3303 & GHRP-6 Supplier

NewsAug.23,2025

-

Wholesale CAS: 79099-07-3 Factories - China Pharma Grade

NewsAug.22,2025

-

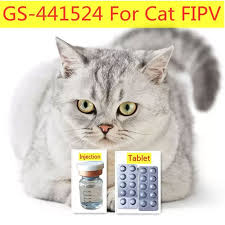

GS-441524 for White Liquid & Pill Factories - Trusted Source

NewsAug.11,2025