- +86-13363869198

- weimiaohb@126.com

Dec . 09, 2024 17:45 Back to list

PMK CAS 52190-28-0 Production Overview and Key Manufacturers Insights

Understanding PMK CAS 52190-28-0 Factories and Production Insights

The compound PMK, known chemically as 3-Pyrrolidinopropiophenone, has gained significant attention in various industries due to its utility in synthesizing other complex organic compounds. The compound's corresponding CAS number, 52190-28-0, serves as a unique identifier that aids in the regulation and research of this substance. With the increasing demand for PMK in pharmaceutical and chemical synthesis, several factories around the globe have ramped up production to meet the needs of their respective markets.

Overview of PMK Production

Factories that manufacture PMK typically follow a series of rigorous chemical processes to ensure high purity and yield. The production of PMK involves several key steps, including the reaction of precursors under controlled conditions, purification stages such as recrystallization and distillation, and rigorous quality control measures to ensure the product meets regulatory standards.

In a typical PMK production facility, operations begin with the sourcing of raw materials, which are predominantly organic chemicals. Advanced industrial techniques are employed to initiate the chemical reactions necessary for synthesizing PMK. Modern factories utilize state-of-the-art equipment, such as reactors, separators, and chromatography setups, to streamline production and increase efficiency.

Quality Control and Safety Measures

Given the potential risks associated with the chemicals involved in PMK production and its applications, factories prioritize stringent quality control. This includes regular testing for purity using techniques such as High-Performance Liquid Chromatography (HPLC) and Nuclear Magnetic Resonance (NMR) spectroscopy. Moreover, adhering to safety regulations is paramount; factories implement comprehensive safety protocols to protect workers and the environment from hazardous exposures.

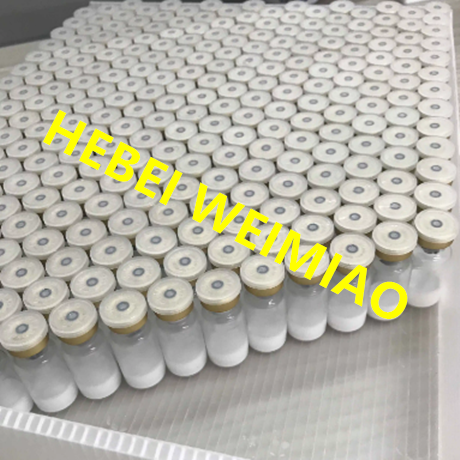

pmk cas 52190-28-0 factories

Regulatory compliance is also critical for PMK manufacturing plants. Factories must adhere to local and international guidelines regarding the handling and disposal of chemicals. This involves maintaining detailed records of production processes and having robust incident response plans in place to address any unforeseen emergencies.

The Market Demand for PMK

The demand for PMK has surged recently due to its applications in synthesizing various pharmaceuticals and research compounds. It is particularly sought after in the production of anesthetics and other medicinal compounds, which further drives its market value. As industries continue to innovate and develop new synthetic routes, PMK is likely to remain a key player in chemical manufacturing.

Furthermore, the global trend towards sustainable chemistry is influencing production practices. Many factories are exploring greener methods of manufacturing PMK, such as utilizing renewable resources and minimizing waste. This shift not only helps in meeting environmental regulations but also caters to the growing consumer demand for sustainable products.

Future Perspectives

Looking ahead, the landscape of PMK manufacturing is expected to evolve with advancements in technology. Factories may adopt more automated systems to enhance efficiency and reduce the margin of error in chemical processes. Additionally, the integration of artificial intelligence and machine learning could optimize production schedules and enhance quality control measures.

In conclusion, PMK (CAS 52190-28-0) holds a significant position within the chemical industry, driven by its diverse applications and growing market demand. Factories involved in its production face the dual challenge of ensuring high-quality output while adhering to regulatory requirements and environmental considerations. As the industry progresses, innovation in manufacturing processes will likely define the future of PMK production, paving the way for sustainable and efficient chemical synthesis.

-

AI-Optimized CAS: 79099-07-3 Factories for High Yield

NewsAug.01,2025

-

Premium CAS 1451-83-8 Factory with GPT-4 Turbo | AI-Optimized

NewsJul.31,2025

-

Pharmaceutical Intermediates - AI-Optimized Synthesis & Purity

NewsJul.31,2025

-

Top CAS: 79099-07-3 Factories & Wholesale Supplier from China

NewsJul.30,2025

-

High-Quality GS-441524 for White Liquid Type Factories & Suppliers

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale – Reliable Supply

NewsJul.29,2025