- +86-13363869198

- weimiaohb@126.com

Nov . 08, 2024 19:54 Back to list

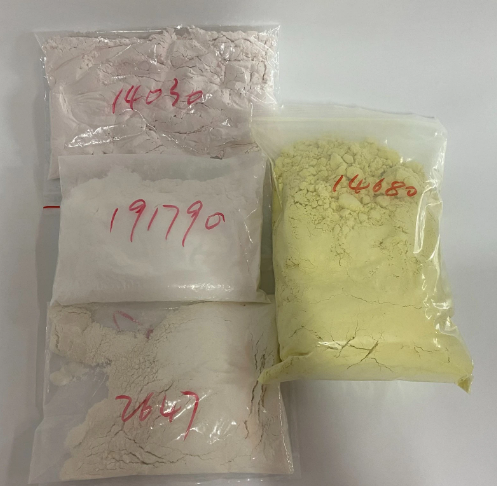

phenacitin powder cas 62-44-2 manufacturers

The Manufacturers of Phenacetin Powder (CAS 62-44-2)

Phenacetin, with the chemical formula C8H9NO2 and a CAS number of 62-44-2, is a synthetic compound that has historically been used as a pain reliever and antipyretic. Originally introduced in the late 19th century, phenacetin gained popularity as an analgesic medication before it was withdrawn from the market in many countries due to safety concerns related to its long-term use, including associations with renal toxicity and the development of certain types of cancer. As a result, most modern manufacturers focus on producing phenacetin for industrial or research purposes rather than for direct pharmaceutical use.

The Role of Manufacturers

Manufacturers of phenacetin powder play a crucial role in ensuring that the compound meets required purity standards and complies with safety regulations. These manufacturers may operate in various sectors, including the pharmaceutical, chemical, and research industries. Companies that produce phenacetin must implement strict quality control protocols, given the substance's past reputation and the need to assure consumers of its safety for research usage, when applicable.

Sourcing Raw Materials

The production of phenacetin typically begins with the sourcing of raw materials. Manufacturers often procure aniline and acetic anhydride as the primary reagents to synthesize phenacetin. The quality of these raw materials is critical; impurities can lead to hazardous outcomes in both the production process and the final product. Reputable manufacturers engage in thorough vetting of their suppliers to ensure that they meet the requisite standards for chemical purity and safety.

Production Process

phenacitin powder cas 62-44-2 manufacturers

The synthesis of phenacetin involves a process known as acetylation, where aniline is reacted with acetic anhydride to form phenacetin. This process requires careful control of reaction conditions, including temperature and reaction time, to optimize yield and minimize byproducts. After synthesis, the phenacetin undergoes several purification steps, including crystallization and filtration, to obtain a high-purity final product.

Quality Control and Assurance

Given the historical concerns regarding phenacetin, manufacturers maintain rigorous quality control measures throughout the production process. This includes the use of high-performance liquid chromatography (HPLC) and gas chromatography (GC) techniques to analyze the purity of the synthesized powder. Manufacturers also conduct stability testing, storage assessments, and compliance checks with regulatory guidelines established by organizations such as the FDA (Food and Drug Administration) and EMA (European Medicines Agency).

Market Demand and Applications

Despite its limitations in therapeutic contexts, there remains a demand for phenacetin in research applications, especially in fields such as organic chemistry, where it is used as an intermediate or reference substance. Additionally, phenacetin can be utilized in the manufacturing of other chemical compounds, serving as a precursor for various pharmaceuticals and agrochemicals. Manufacturers, therefore, often position themselves to cater to niche markets that require this compound for legitimate scientific and industrial purposes.

Conclusion

The landscape for phenacetin powder manufacturers is shaped by its historical context, strict regulatory frameworks, and evolving applications in research and industry. While concerns over its safety have limited its availability as a pharmaceutical product, the demand for high-quality phenacetin for research and chemical synthesis remains. Manufacturers dedicated to producing phenacetin must navigate these complexities with robust quality control measures and a commitment to safety and compliance, ensuring that they provide a reliable product to their clients in various sectors. As the market continues to evolve, the importance of reputable manufacturers in providing quality phenacetin will remain paramount.

-

Top CAS: 79099-07-3 Factories & Wholesale Supplier from China

NewsJul.30,2025

-

High-Quality GS-441524 for White Liquid Type Factories & Suppliers

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale – Reliable Supply

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale - Reliable Solutions

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates Supplier for Global Market

NewsJul.28,2025

-

GS-441524 for White Liquid Type Factories – High Purity & Reliable Supply

NewsJul.28,2025