- +86-13363869198

- weimiaohb@126.com

Nov . 18, 2024 08:00 Back to list

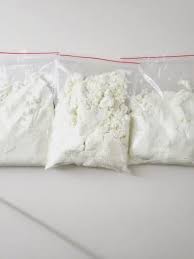

methyl 3-methoxyacrylate cas 34846-90-7 manufacturer

Methyl 3-Methoxyacrylate Composition, Uses, and Manufacturers

Methyl 3-methoxyacrylate is an important chemical compound classified under acrylic esters. Its chemical formula is C6H10O3, and it is often represented by the CAS number 34846-90-7. This compound is well-regarded for its utility in various industrial applications, particularly in the fields of coatings, adhesives, and polymers. As industries continue to evolve, the demand for high-quality methyl 3-methoxyacrylate has also increased, making a strong understanding of its properties, uses, and sources essential for manufacturers and consumers alike.

Properties of Methyl 3-Methoxyacrylate

Methyl 3-methoxyacrylate is characterized by its colorless liquid form and pleasant odor. It is soluble in organic solvents, making it an ideal component in different formulations. One of the most notable features of this compound is its reactivity; it is capable of undergoing polymerization, which allows it to form long-chain molecules that are crucial for creating robust materials. The compound is particularly valued for its ability to enhance flexibility and durability when incorporated into polymer matrices, making it a sought-after ingredient in various products.

Applications in Industry

Methyl 3-methoxyacrylate finds extensive application in the production of coatings and paints. Its chemical properties allow it to contribute to the formation of films that are both resilient and aesthetically pleasing. Coatings derived from this ester offer excellent adhesion, making them suitable for use on a wide range of substrates, including metals, plastics, and wood. Additionally, the presence of methoxy groups in its structure enhances the performance of these coatings under various environmental conditions, such as humidity and temperature fluctuations.

In the adhesive industry, methyl 3-methoxyacrylate plays a crucial role in formulating strong, flexible adhesives that can bond different materials together effectively. The reactivity of the compound facilitates rapid curing, enabling manufacturers to produce high-throughput adhesive solutions for various applications, ranging from construction to automotive industries.

Furthermore, this compound is used in the synthesis of polymers with specific characteristics tailored to the needs of product manufacturers. By varying the ratios of methyl 3-methoxyacrylate with other monomers, manufacturers can produce copolymers with desired mechanical and thermal properties.

Finding Reliable Manufacturers

methyl 3-methoxyacrylate cas 34846-90-7 manufacturer

The rising demand for methyl 3-methoxyacrylate has led to an increase in the number of manufacturers offering this compound

. When seeking a reliable supplier, it is crucial to evaluate several factors1. Quality Assurance Look for manufacturers that adhere to strict quality control protocols. Certification from internationally recognized bodies indicates that the product meets the required purity standards.

2. Production Capacity Reliable manufacturers should have the capability to meet bulk orders consistently. Understanding their production capabilities can help ensure timely delivery without compromising quality.

3. Technical Expertise Manufacturers with a strong technical background can provide valuable insights regarding the applications and processing of methyl 3-methoxyacrylate, aiding customers in optimizing its use in their specific products.

4. Customization Options The ability to customize formulations based on specific customer needs can be a significant advantage. Engaging with manufacturers that offer flexibility in production can help businesses innovate new products.

5. Customer Support Strong customer service is vital for addressing inquiries and resolving issues promptly. Reliable manufacturers should be accessible and responsive to their customers' needs.

Conclusion

Methyl 3-methoxyacrylate (CAS 34846-90-7) serves as a versatile compound in numerous industrial sectors, from coatings to adhesives and specialty polymers. Understanding its properties and applications is vital for manufacturers aiming to leverage its benefits. As the industry grows, finding high-quality, reliable suppliers is more important than ever to ensure the success of products utilizing this essential acrylate ester. With the right partnerships, businesses can enhance their offerings and keep pace with the evolving market demands.

-

Top CAS: 79099-07-3 Factories & Wholesale Supplier from China

NewsJul.30,2025

-

High-Quality GS-441524 for White Liquid Type Factories & Suppliers

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale – Reliable Supply

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale - Reliable Solutions

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates Supplier for Global Market

NewsJul.28,2025

-

GS-441524 for White Liquid Type Factories – High Purity & Reliable Supply

NewsJul.28,2025