- +86-13363869198

- weimiaohb@126.com

Jul . 28, 2024 09:05 Back to list

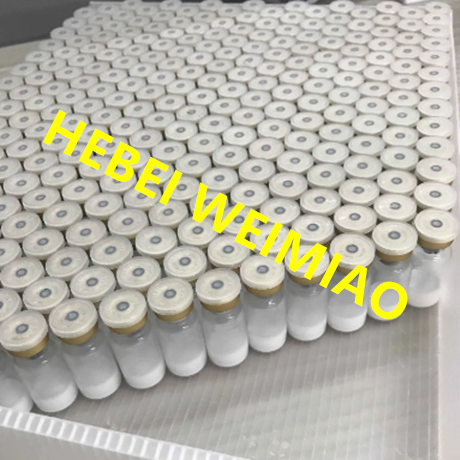

High-Quality Bromazolam Powder Production Facility for Pharmaceutical and Research Applications

The Bromazolam Powder Factory An Insight into Production and Safety Measures

In recent years, the demand for pharmaceutical compounds has surged, leading to the establishment of dedicated factories that specialize in the production of various substances. One such compound gaining attention is Bromazolam, a medication that falls under the benzodiazepine class. This article provides an overview of a hypothetical Bromazolam powder factory, highlighting its operations, production processes, and the paramount importance of safety measures.

Bromazolam is a potent anxiolytic and sedative, utilized primarily in medical settings to treat anxiety and sleep disorders. As with any pharmaceutical, the production of Bromazolam requires stringent adherence to regulatory standards and quality control processes to ensure safety and efficacy. A specialized factory designed for the production of Bromazolam powder is equipped with the latest technology and facilities to facilitate the efficient synthesis and formulation of this compound.

The Bromazolam Powder Factory An Insight into Production and Safety Measures

Chemical reactors are employed to facilitate the reactions, and the environment is kept under strict temperature and pressure controls. Advanced monitoring systems are in place to ensure that every batch meets the regulatory standards required for pharmaceutical products. After synthesis, the Bromazolam compound is typically crystallized, then dried, leading to the formation of a fine powder.

bromazolam powder factory

Post-production, the Bromazolam powder undergoes rigorous testing to ensure it meets purity specifications. This is primarily conducted in well-equipped quality control laboratories within the factory. Testing includes techniques such as chromatography and spectrometry, which are critical in identifying the presence of impurities and confirming the concentration of Bromazolam in the final product. Only after passing all these tests is the product packaged and labeled for distribution.

A vital aspect of any pharmaceutical factory, including one producing Bromazolam powder, is the implementation of safety measures. The handling of chemicals always poses inherent risks, and thus, factories must adhere to occupational safety guidelines rigorously. Workers in the Bromazolam factory are required to wear appropriate personal protective equipment (PPE), which includes gloves, masks, and goggles, to minimize exposure to potentially hazardous substances.

Moreover, the factory is outfitted with proper ventilation systems and emergency response protocols to manage any accidental spills or exposure. Regular safety drills are conducted to prepare employees for such emergencies. In addition, environmental considerations are taken into account, ensuring that waste products from the manufacturing process are disposed of in compliance with environmental regulations.

Finally, the distribution of Bromazolam powder is subjected to regulatory oversight, ensuring that it is delivered to licensed pharmacies and medical facilities only. This control is crucial to prevent misuse, given the potential for abuse associated with benzodiazepines.

In conclusion, a Bromazolam powder factory is a complex yet highly regulated environment dedicated to producing a medication that plays a significant role in managing anxiety and sleep disorders. The production process involves sophisticated chemical synthesis, rigorous quality control, and strict safety measures, all designed to ensure that the final product is safe, effective, and compliant with pharmaceutical standards. As the demand for such medications continues to evolve, so too will the practices and technologies employed in their production, emphasizing the need for continuous adaptation and vigilance in the pharmaceutical manufacturing industry.

-

Top CAS: 79099-07-3 Factories & Wholesale Supplier from China

NewsJul.30,2025

-

High-Quality GS-441524 for White Liquid Type Factories & Suppliers

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale – Reliable Supply

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale - Reliable Solutions

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates Supplier for Global Market

NewsJul.28,2025

-

GS-441524 for White Liquid Type Factories – High Purity & Reliable Supply

NewsJul.28,2025