- +86-13363869198

- weimiaohb@126.com

Nov . 05, 2024 15:30 Back to list

cas 88-99-3 phthalic acid factories

The Importance of Phthalic Acid in Industry

Phthalic acid, also known by its Chemical Abstracts Service (CAS) number 88-99-3, plays a crucial role in various industrial applications. This aromatic dicarboxylic acid, with the molecular formula C8H6O4, is derived from the oxidation of naphthalene or ortho-xylene. Over the years, the demand for phthalic acid has steadily grown due to its diverse applications, particularly in the production of plasticizers, resins, and dyes. Understanding the manufacturing processes and the impact of phthalic acid factories is vital to fully appreciate its significance in modern industry.

Manufacturing Processes

Phthalic acid is primarily produced through the catalytic oxidation of naphthalene or ortho-xylene in the presence of air or oxygen. The process involves heating these precursors to high temperatures where catalytic agents, often based on vanadium, are used to facilitate the reaction. This method ensures efficient production and a high yield of phthalic acid.

Phthalic acid can also be produced by the hydrolysis of phthalic anhydride, which is another important chemical derived from similar precursor materials. The reaction conditions must be carefully controlled to prevent the decomposition of the acid, which can affect the quality of the final product.

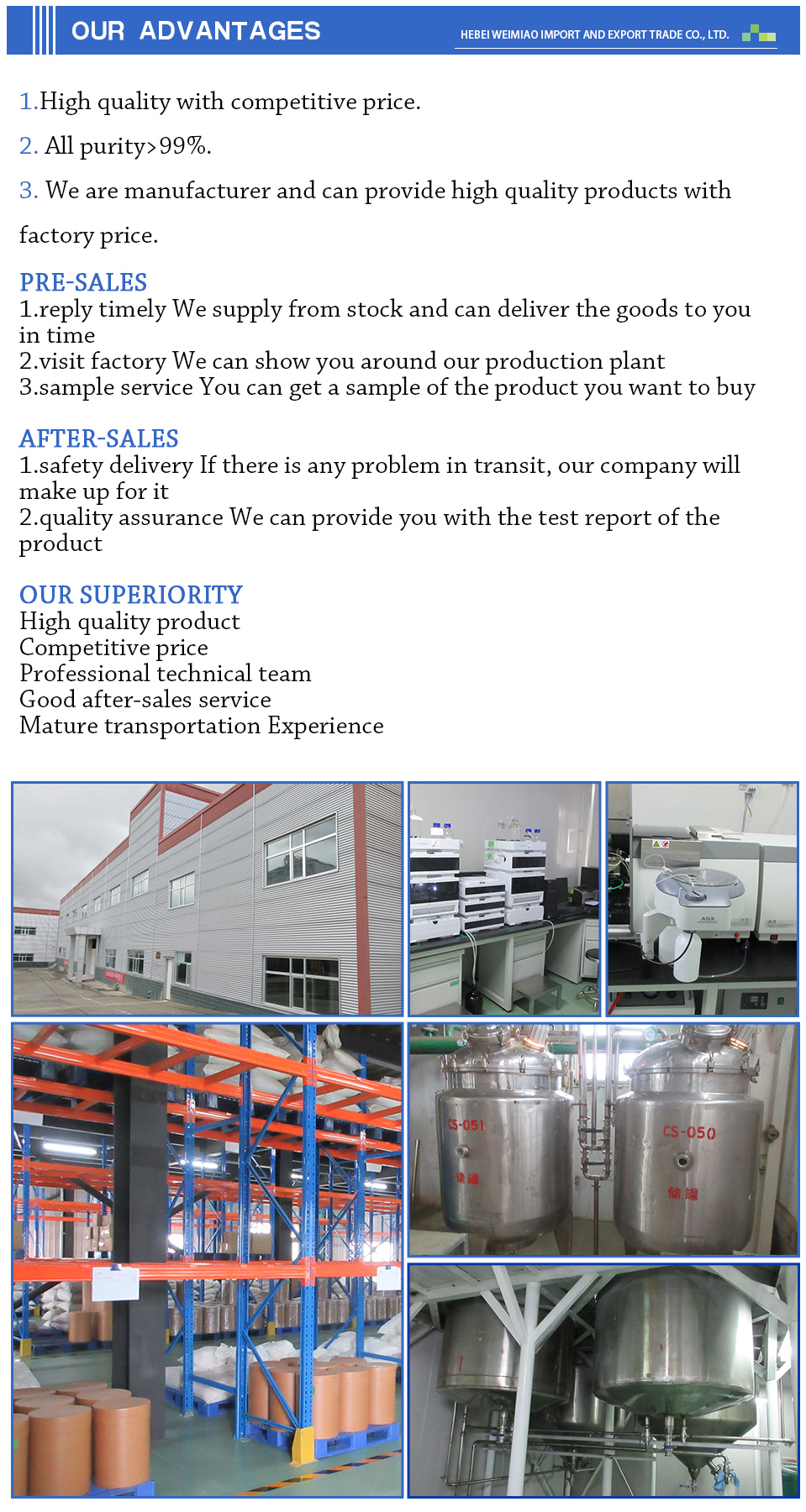

Phthalic acid factories are equipped with advanced technology to ensure optimal reaction conditions and safety measures to minimize emissions and environmental impact. Modern manufacturing processes are increasingly focusing on sustainability, employing measures to reduce waste and improve energy efficiency.

Applications in Industry

The primary application of phthalic acid is as an intermediate in the production of plasticizers. These are compounds added to plastics to increase their flexibility, durability, and workability. One of the most common plasticizers derived from phthalic acid is dioctyl phthalate (DOP). Plastics treated with DOP are utilized in a myriad of products, including cables, flooring, and toys, making phthalic acid crucial to the manufacturing industry.

cas 88-99-3 phthalic acid factories

In addition to plasticizers, phthalic acid is used in the production of alkyd resins, which are essential in paints and coatings. These resins provide excellent adhesion, durability, and weather resistance, making them ideal for a variety of applications, from automotive finishes to industrial coatings. The demand for environmentally-friendly paints has led to innovations in phthalic acid derivatives to create low-VOC (volatile organic compound) formulations, contributing to a greener industry.

Moreover, phthalic acid derivatives are important in the dye industry, where they serve as intermediates in manufacturing various colorants. This versatility makes phthalic acid an integral component in numerous products encountered in everyday life.

Environmental and Regulatory Considerations

Despite its industrial importance, the production and use of phthalic acid have been subjected to scrutiny due to environmental and health concerns. Research has indicated that certain phthalates, particularly those derived from phthalic acid, may pose risks related to hormonal disruption and other health issues. As a consequence, regulatory bodies around the world have implemented stricter controls on the use of certain phthalates, prompting manufacturers to explore safer alternatives.

Phthalic acid manufacturers are increasingly investing in research to develop sustainable processes and non-toxic alternatives to conventional plasticizers. This shift reflects the industry's commitment to environmental stewardship and public health.

Conclusion

Phthalic acid is a vital chemical in the manufacturing landscape, with applications ranging from plasticizers to resins and dyes. While its utility is undeniable, the industry must balance production with environmental safety and health considerations. As technological advancements continue to shape the manufacturing processes, the future of phthalic acid looks promising, particularly as factories evolve to adopt greener practices. Understanding these dynamics is essential for stakeholders aiming to navigate the complexities of the chemical industry.

-

Top CAS: 79099-07-3 Factories & Wholesale Supplier from China

NewsJul.30,2025

-

High-Quality GS-441524 for White Liquid Type Factories & Suppliers

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale – Reliable Supply

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale - Reliable Solutions

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates Supplier for Global Market

NewsJul.28,2025

-

GS-441524 for White Liquid Type Factories – High Purity & Reliable Supply

NewsJul.28,2025