- +86-13363869198

- weimiaohb@126.com

Dec . 04, 2024 08:41 Back to list

cas 157115-85-0 factories

Exploring the Production of CAS 157115-85-0 A Comprehensive Overview

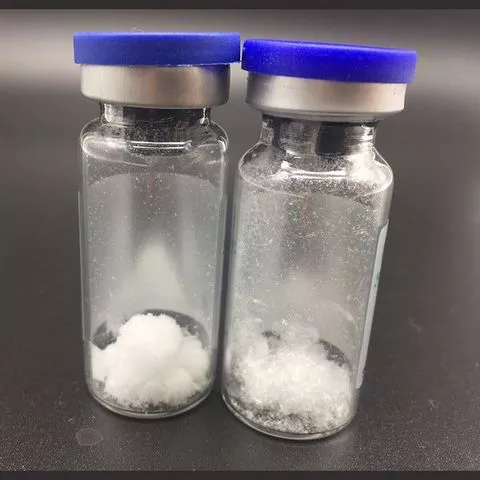

CAS 157115-85-0, also known as Terbinafine hydrochloride, is an antifungal medication commonly used to treat a variety of fungal infections, including those of the skin and nails. It is particularly effective against dermatophytes, which are a type of fungus that causes conditions such as athlete's foot, ringworm, and toenail fungus. Given the increasing prevalence of fungal infections and the demand for effective treatments, the production of Terbinafine hydrochloride in factories has become a significant focus in the pharmaceutical industry.

Manufacturing Process

The production of Terbinafine involves a series of chemical reactions that take place in pharmaceutical manufacturing facilities. Typically, the synthesis starts with the preparation of the base compound, which undergoes various chemical transformations to produce the final drug. The process includes steps like condensation reactions, which are critical in forming the essential structures of the compound. Quality control at each stage is crucial to ensure that the active pharmaceutical ingredient (API) meets stringent regulatory standards.

Raw Materials and Components

To manufacture Terbinafine hydrochloride, several raw materials are required. These can include specific chemicals, solvents, and catalysts used in the synthesis process. Factories must source high-purity raw materials to ensure the efficacy and safety of the final product. The logistics of acquiring these materials play a vital role in the efficiency of production and the overall cost of the drug.

Factory Infrastructure

Pharmaceutical factories that produce Terbinafine hydrochloride are equipped with advanced technologies and stringent safety protocols. The infrastructure typically includes clean rooms, which are essential for maintaining the necessary sterile environment for drug production. These facilities are designed to minimize contamination risks and ensure that the manufacturing process complies with Good Manufacturing Practices (GMP).

cas 157115-85-0 factories

Quality Assurance

Quality assurance is a pivotal aspect of the production chain for Terbinafine hydrochloride. Factories implement thorough quality control measures to test intermediate and final products for potency, purity, and safety. This involves a series of analytical techniques, including High-Performance Liquid Chromatography (HPLC) and mass spectrometry, to assess the quality of the compound. Regulatory bodies like the FDA and EMA closely monitor these practices, and factories must adhere to strict guidelines to maintain compliance.

Market Demand and Economic Impact

The rising incidence of fungal infections, coupled with an aging population, has significantly fueled the demand for effective antifungal medications like Terbinafine hydrochloride. As a result, pharmaceutical factories have ramped up their production capacities to meet this growing need. The economic impact of this increased production is substantial, contributing to job creation within the manufacturing sector and providing essential treatments to millions of patients worldwide.

Challenges in Production

Despite the robust demand for Terbinafine hydrochloride, factories face several challenges in the production process. One major concern is ensuring the sustainability of raw material supplies, as fluctuations in the availability of essential chemicals can impact manufacturing timelines. Additionally, maintaining compliance with evolving regulatory standards requires continuous investments in technology and training for staff. Factories must also navigate the complexities of global supply chains, which can be affected by geopolitical factors and transportation issues.

Conclusion

In summary, the production of CAS 157115-85-0, or Terbinafine hydrochloride, represents an intricate and vital component of the pharmaceutical industry. Through advanced manufacturing processes, stringent quality control, and the commitment to meeting market demand, factories play a crucial role in delivering effective treatments for fungal infections. As the landscape of healthcare continues to evolve, the importance of efficient and compliant production practices for essential medications like Terbinafine will only grow, underscoring the pivotal role of pharmaceutical manufacturing in public health.

-

Premium Pharma Intermediates | AI-Optimized Synthesis

NewsAug.03,2025

-

GS-441524 White Liquid Production for Factories | AI-Optimized

NewsAug.02,2025

-

AI-Optimized CAS: 79099-07-3 Factories for High Yield

NewsAug.01,2025

-

Premium CAS 1451-83-8 Factory with GPT-4 Turbo | AI-Optimized

NewsJul.31,2025

-

Pharmaceutical Intermediates - AI-Optimized Synthesis & Purity

NewsJul.31,2025

-

Top CAS: 79099-07-3 Factories & Wholesale Supplier from China

NewsJul.30,2025