- +86-13363869198

- weimiaohb@126.com

डिसेंबर . 21, 2024 14:19 Back to list

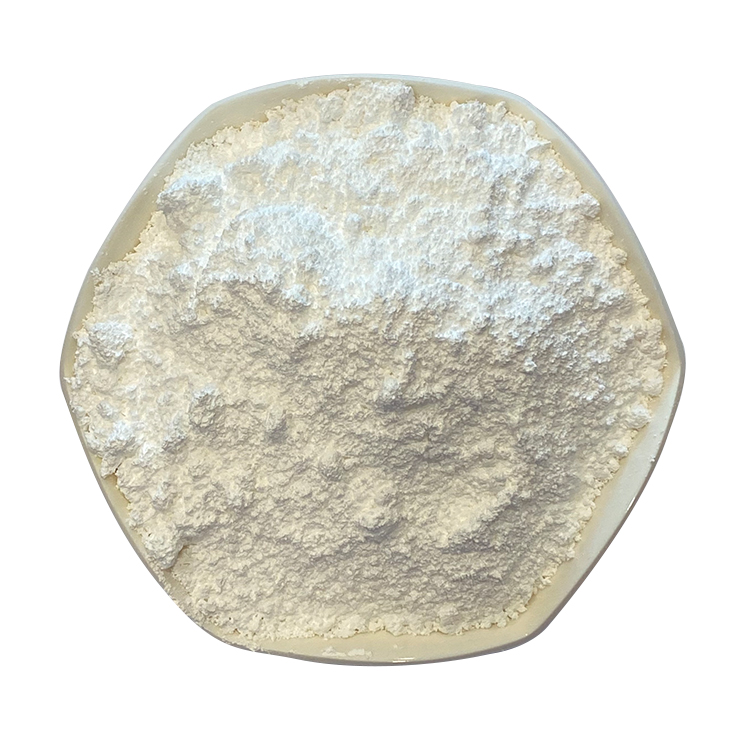

Bromazolam Powder Production Facility for Quality Pharmaceutical Manufacturing

The Bromazolam Powder Factory A Modern Approach to Pharmaceutical Production

In the realm of pharmaceuticals, the production of high-quality compounds is paramount. One such compound that has gained attention in recent years is bromazolam, a benzodiazepine known for its anxiolytic properties. The emergence of bromazolam has led to the establishment of specialized facilities dedicated to its synthesis and commercialization. This article explores the various aspects of a bromazolam powder factory, focusing on its production processes, quality control measures, and the implications of its usage.

Understanding Bromazolam

Bromazolam is categorized under the class of benzodiazepines, which are psychoactive drugs that act on the central nervous system. Often used in the treatment of anxiety and sleep disorders, bromazolam is particularly valued for its sedative and muscle relaxant properties. As with any pharmaceutical compound, the need for reliable and effective production methods cannot be overstated, especially considering the regulatory frameworks that govern drug safety and efficacy.

The Production Process

The first step in the production of bromazolam at a dedicated factory involves the procurement of raw materials, which must meet stringent quality standards. The synthesis of bromazolam typically requires specific chemical reagents, which are handled in controlled environments to prevent contamination. The factory is equipped with state-of-the-art machinery that enables the precise mixing and reaction of these compounds under carefully monitored conditions.

After the synthesis phase, the compound is subjected to rigorous purification processes. This crucial step ensures that any impurities or residual solvents are removed. The purified bromazolam is then converted into a powder form, which is easy to package and distribute. Throughout this process, the factory adheres to good manufacturing practices (GMP) to ensure compliance with international standards.

Quality Control Measures

bromazolam powder factory

Quality control is an integral part of the production at a bromazolam powder factory. Each batch of bromazolam undergoes extensive testing to verify its purity and potency. Sophisticated analytical techniques, such as high-performance liquid chromatography (HPLC) and mass spectrometry, are employed to analyze the product’s chemical composition. These measures not only guarantee that the product meets the required specifications but also provide transparency for regulators and consumers alike.

In addition to testing the final product, the factory must also monitor the production environment. This includes regular inspections of equipment, cleanliness, and personnel hygiene to minimize the risk of contamination. A comprehensive quality assurance system is in place, allowing for traceability from raw materials to the final product, which is critical in the case of any adverse effects or product recalls.

Implications of Bromazolam Production

The production of bromazolam powder comes with both opportunities and challenges. On one hand, the availability of bromazolam can provide relief to individuals suffering from anxiety disorders, contributing positively to public health. On the other hand, the potential for misuse or addiction poses significant risks. Therefore, it is essential that bromazolam is marketed responsibly and prescribed judiciously.

Regulatory agencies play a crucial role in overseeing the use of bromazolam and other controlled substances. The factory must ensure that its operations align with the legal frameworks governing the production and distribution of benzodiazepines. This involves close collaboration with health authorities to provide education on safe usage, potential side effects, and the importance of following prescribed dosages.

Conclusion

The bromazolam powder factory represents a critical element in the pharmaceutical landscape, combining advanced technology with a commitment to quality and safety. As the demand for effective anxiety treatments continues to rise, the production of bromazolam will likely play an increasingly prominent role. However, it is essential that all stakeholders—manufacturers, healthcare providers, and patients—are aware of the responsibilities that come with such a powerful medication. By adhering to rigorous quality standards and promoting responsible use, bromazolam can be a valuable tool in the management of anxiety and related disorders.

-

GS-441524 White Liquid Production for Factories | AI-Optimized

NewsAug.02,2025

-

AI-Optimized CAS: 79099-07-3 Factories for High Yield

NewsAug.01,2025

-

Premium CAS 1451-83-8 Factory with GPT-4 Turbo | AI-Optimized

NewsJul.31,2025

-

Pharmaceutical Intermediates - AI-Optimized Synthesis & Purity

NewsJul.31,2025

-

Top CAS: 79099-07-3 Factories & Wholesale Supplier from China

NewsJul.30,2025

-

High-Quality GS-441524 for White Liquid Type Factories & Suppliers

NewsJul.29,2025