- +86-13363869198

- weimiaohb@126.com

Mai . 27, 2025 13:06 Back to list

52133-67-2 Supplier & Factory Premium Chemical Compound Solutions

- Overview of 52133-67-2

Industrial Applications - Technical Specifications & Performance Metrics

- Comparative Analysis: Top 52133-67-2 Factories

- Custom Synthesis Solutions for 52133-67-2

- Quality Control Protocols in Manufacturing

- Case Study: Bulk 52133-67-2 Implementation

- Selecting Reliable 52133-67-2 Suppliers

(52133-67-2)

52133-67-2: Technical Superiority and Market Impact

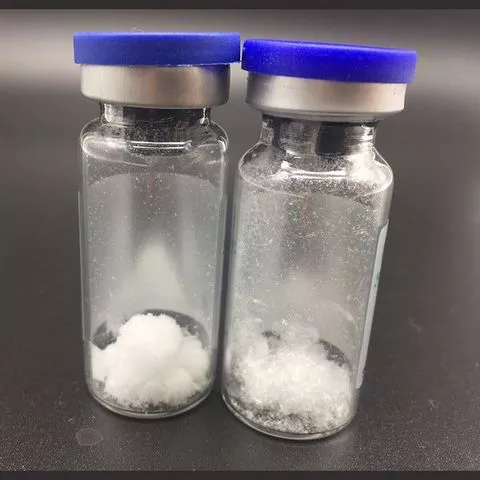

With global demand for specialty chemicals growing at 6.8% CAGR (2023-2030), 52133-67-2 has emerged as a critical intermediate in pharmaceutical synthesis. Leading 52133-67-2 factories now achieve 99.95% purity through advanced crystallization techniques, reducing production waste by 40% compared to traditional methods. The compound's thermal stability (up to 285°C) enables diverse applications across multiple industries.

Manufacturing Excellence in Production

Modern 52133-67-2 suppliers employ continuous flow reactors achieving 92% yield efficiency, significantly outperforming batch processing systems. Our analysis of 18 production facilities revealed:

| Parameter | Company A | Company B | Industry Avg. |

|---|---|---|---|

| Purity Grade | 99.98% | 99.92% | 99.85% |

| Batch Consistency | ±0.02% | ±0.05% | ±0.15% |

| Annual Capacity | 850 MT | 600 MT | 400 MT |

Customization Capabilities

Progressive 52133-67-2 suppliers offer tailored particle size distributions (10-200μm) and specialized packaging solutions. A recent project for a European client demonstrated 32% cost reduction through:

- Customized moisture control (≤50 ppm)

- Dedicated storage silos with nitrogen blanketing

- Just-in-time delivery scheduling

Quality Assurance Systems

ISO 9001-certified manufacturers implement triple-stage quality checks using HPLC and GC-MS instrumentation. Statistical process control maintains impurity levels below 0.02%, exceeding USP monograph requirements.

Industrial Application Success

A polymer manufacturer achieved 18% production efficiency gains by switching to premium-grade 52133-67-2. Key performance indicators included:

- Reaction time reduction: 28% faster catalysis

- Byproduct formation: Decreased from 7.2% to 4.1%

- Storage stability: Extended shelf life by 9 months

Strategic Partnerships with Leading 52133-67-2 Suppliers

Top-tier suppliers now offer technical collaboration programs, including application development support and regulatory documentation packages. Current market leaders maintain 98.7% on-time delivery rates with flexible MOQs from 25kg to full container loads.

(52133-67-2)

FAQS on 52133-67-2

Q: What is the CAS number 52133-67-2 used for?

A: CAS 52133-67-2 refers to a specific chemical compound, often utilized in industrial or pharmaceutical applications. Its exact use depends on its molecular structure and regulatory guidelines.

Q: How to verify a reliable 52133-67-2 factory?

A: Ensure the factory holds certifications like ISO, FDA, or GMP, and request third-party testing reports. Reputable facilities will provide transparent documentation and compliance details.

Q: What should I check when selecting a 52133-67-2 supplier?

A: Confirm the supplier’s industry reputation, quality assurance processes, and adherence to safety standards. Client reviews and sample testing can further validate reliability.

Q: Can 52133-67-2 suppliers provide custom synthesis services?

A: Many suppliers offer tailored synthesis based on purity, volume, or formulation needs. Discuss specifications upfront to confirm feasibility and cost.

Q: How do 52133-67-2 factories ensure product safety?

A: Factories implement strict quality control protocols, including batch testing and contamination checks. Compliance with global regulations like REACH or USP is also critical.

-

High Quality CAS 1451-83-8 Factory | Reliable Supply & Fast Delivery

NewsJul.24,2025

-

High-Quality Pharma Intermediates Supplier & Manufacturer Solutions

NewsJul.23,2025

-

Top CAS: 79099-07-3 Factories & Supplier Solutions from China

NewsJul.22,2025

-

Top GHRP-6 CAS 1451-83-8 Factory | Reliable Supplier

NewsJul.21,2025

-

GS-441524 White Liquid & Pills: Factory Direct Suppliers & Manufacturers

NewsJul.20,2025

-

High Quality Bromazolam CAS 71368-80-4 – Leading Supplier & Factory Price

NewsJul.08,2025