- +86-13363869198

- weimiaohb@126.com

Aug . 07, 2024 02:50 Back to list

Exploring Manufacturers of Hydroxychloroquine Sulfate CAS 747-36-4 and Their Production Processes

Hydroxychloroquine Sulfate An Overview of Its Production and Impact

Hydroxychloroquine sulfate, a medication commonly known for its use in treating conditions such as malaria, lupus, and rheumatoid arthritis, has been a subject of significant interest, especially in light of recent global health crises. With the increase in demand for this drug, understanding the production process and the role of factories in manufacturing hydroxychloroquine sulfate becomes paramount.

The chemical compound hydroxychloroquine sulfate is represented by the CAS number 747-36-4. It is derived from chloroquine, a drug that has been used for decades to combat malaria. Hydroxychloroquine is considered to have a better safety profile and is generally better tolerated than chloroquine, making it a preferred choice for long-term management of autoimmune diseases.

The production of hydroxychloroquine sulfate involves several stages, primarily taking place in pharmaceutical manufacturing facilities. These factories are equipped with advanced technology and adhere to strict regulatory guidelines to ensure the quality and safety of the final product.

The Manufacturing Process

1. Sourcing Raw Materials The first step in the production process is sourcing high-quality raw materials. The active pharmaceutical ingredient (API) must meet stringent quality standards to ensure efficacy and safety. Factories partner with reputable suppliers to obtain these materials.

2. Chemical Synthesis Once the raw materials are procured, the synthesis of hydroxychloroquine begins. In general, the synthesis involves multiple chemical reactions that convert precursor molecules into the final drug. Factories utilize scalable and efficient synthetic routes to maximize yield and minimize waste.

3. Purification and Formulation After synthesis, the compound undergoes purification to remove any impurities. This step is crucial, as residual substances can affect the quality of the medication. Following purification, hydroxychloroquine sulfate is formulated into various dosage forms, including tablets and injections.

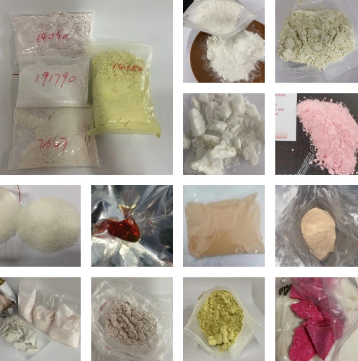

hydroxychloroquine sulfate cas747-36-4 factories

4. Quality Control Quality assurance is a critical aspect of the manufacturing process. Factories employ rigorous testing protocols to ensure that the final product meets the required pharmacological standards. This includes checking for purity, potency, and stability through advanced analytical techniques.

5. Packaging and Distribution Once quality control checks are passed, the product is packaged in compliance with regulatory guidelines. Proper packaging protects the drug from environmental factors and ensures safe handling during transportation. Factories often have logistics systems in place to facilitate timely distribution to pharmacies and healthcare providers.

Impact and Importance

The availability of hydroxychloroquine sulfate in the global market has made it an essential medication, especially during health crises such as the COVID-19 pandemic, where it was explored as a potential treatment option. The responsive nature of pharmaceutical factories has allowed for accelerated production rates and increased supply in challenging times.

Moreover, the ongoing research into hydroxychloroquine's efficacy in various diseases continues to drive interest in its production. As new studies emerge and treatment guidelines evolve, factories must remain agile in their operations to adapt to changing demands.

Additionally, the production of hydroxychloroquine sulfate highlights the importance of maintaining robust supply chains in the pharmaceutical industry. Global cooperation and regulatory compliance are vital in ensuring that high-quality medicines are accessible to those in need.

Conclusion

Hydroxychloroquine sulfate, with its diverse medical applications, underscores the critical role of pharmaceutical factories in drug manufacturing. From the initial sourcing of raw materials to the final distribution of the medication, each step in the production process is essential in ensuring that patients receive safe and effective treatments. As we move forward, the ability of these factories to adapt to new challenges will be vital in managing public health needs and advancing pharmaceutical innovations.

-

GS-441524 for White Liquid Factories: Boost Efficiency & Purity

NewsAug.04,2025

-

Premium Pharma Intermediates | AI-Optimized Synthesis

NewsAug.03,2025

-

GS-441524 White Liquid Production for Factories | AI-Optimized

NewsAug.02,2025

-

AI-Optimized CAS: 79099-07-3 Factories for High Yield

NewsAug.01,2025

-

Premium CAS 1451-83-8 Factory with GPT-4 Turbo | AI-Optimized

NewsJul.31,2025

-

Pharmaceutical Intermediates - AI-Optimized Synthesis & Purity

NewsJul.31,2025