- +86-13363869198

- weimiaohb@126.com

Set . 23, 2024 06:48 Back to list

bromazolam powder factory

The Bromazolam Powder Factory A Glimpse into Production and Quality Control

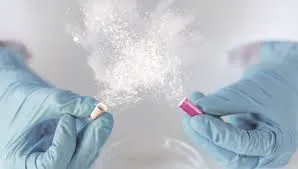

Bromazolam is a benzodiazepine derivative known for its anxiolytic properties and is used in various therapeutic contexts to manage anxiety disorders. The production of bromazolam powder involves a meticulous process that takes place in specialized factories designed to ensure purity and compliance with health regulations.

The process begins with the procurement of high-quality raw materials. These materials must meet stringent standards to guarantee the efficacy and safety of the final product. In a bromazolam powder factory, quality control is paramount. Every batch of raw materials undergoes rigorous testing to confirm its identity, potency, and absence of contaminants. This initial step is crucial, as the safety of the final product hinges on the quality of its components.

The Bromazolam Powder Factory A Glimpse into Production and Quality Control

After the synthesis, the bromazolam undergoes several purification steps. Common methods include crystallization and chromatography, which are used to isolate the active ingredient from byproducts and other impurities. The purification process is essential, as any impurities can alter the pharmacological profile of the drug or lead to adverse effects in patients. Furthermore, each stage of purification is closely monitored through quality control testing, ensuring that only the highest standards are maintained.

bromazolam powder factory

Once the bromazolam powder is ready, it is subjected to additional testing. This includes Physicochemical analyses and microbial testing to ensure that the product is safe for use. The results determine if the powder meets the required specifications set by regulatory authorities. Only after passing these tests can the product be packaged and distributed for commercial use.

Packaging is another critical aspect of the bromazolam production process. The powder must be stored properly to maintain its potency and stability. Factories utilize moisture-proof and air-tight containers to prevent degradation of the product. Additionally, labeling is essential—not only for compliance with regulations but also to inform potential users about dosage, storage conditions, and possible side effects.

Once the bromazolam reaches the market, manufacturers must continue monitoring and ensuring the quality of their products through pharmacovigilance programs. This involves collecting data on the drug's performance in real-world settings and making necessary adjustments based on feedback provided by healthcare professionals and patients.

In summary, bromazolam powder factories play a pivotal role in the pharmaceutical industry. Through rigorous quality control, advanced production techniques, and stringent safety measures, these facilities ensure that bromazolam is produced to the highest standards. This commitment to quality not only safeguards users but also enhances the credibility of the pharmaceutical industry as a whole. As the demand for effective anxiolytic medications continues to grow, the importance of maintaining high production standards remains ever critical.

-

Premium CAS 1451-83-8 Factory with GPT-4 Turbo | AI-Optimized

NewsJul.31,2025

-

Pharmaceutical Intermediates - AI-Optimized Synthesis & Purity

NewsJul.31,2025

-

Top CAS: 79099-07-3 Factories & Wholesale Supplier from China

NewsJul.30,2025

-

High-Quality GS-441524 for White Liquid Type Factories & Suppliers

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale – Reliable Supply

NewsJul.29,2025

-

High-Quality Pharmaceutical Intermediates for Sale - Reliable Solutions

NewsJul.29,2025