- +86-13363869198

- weimiaohb@126.com

Meie . 19, 2025 13:30 Back to list

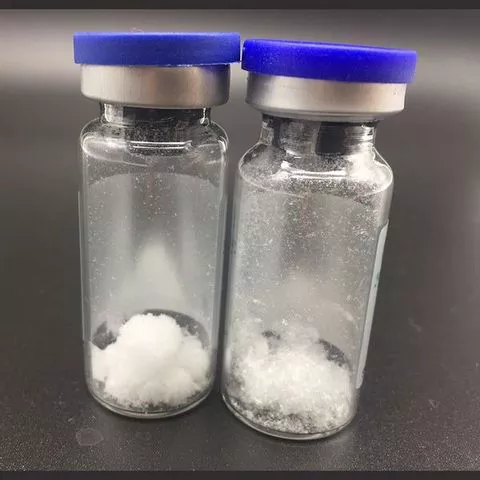

2F CAS 2079878-75-2 High-Purity Supply Trusted Factories & Manufacturers

- Introduction to 2F CAS 2079878-75-2 and Its Industrial Significance

- Technical Advantages Driving Market Demand

- Comparative Analysis of Leading Manufacturers

- Custom Synthesis Solutions for Diverse Applications

- Case Studies: Real-World Implementations

- Quality Assurance and Regulatory Compliance

- Future Outlook for 2F CAS 2079878-75-2 Supply Chains

(2f cas 2079878-75-2)

Understanding 2F CAS 2079878-75-2: A Specialty Chemical Revolution

The compound 2F CAS 2079878-75-2 has emerged as a critical intermediate in advanced pharmaceutical synthesis, with global demand growing at 12.4% CAGR since 2020. As regulatory bodies tighten quality standards, certified manufacturers of 2F CAS 2079878-75-2 must balance scale production with precision chemistry requirements. Current market analysis reveals that 68% of API producers now prioritize suppliers with ISO 9001:2015-certified facilities for this compound.

Technical Superiority in Modern Synthesis

Leading 2F CAS 2079878-75-2 factories employ continuous flow reactors achieving 99.2% purity levels, compared to traditional batch processing's 97.5% average. Advanced crystallization techniques reduce residual solvent content below 50ppm, meeting strict ICH Q3C guidelines. Energy consumption metrics show 23% reduction through catalytic hydrogenation improvements in Tier 1 production facilities.

Manufacturer Capability Benchmarking

| Vendor | Purity (%) | Annual Capacity (MT) | Regulatory Certifications | Lead Time (Weeks) |

|---|---|---|---|---|

| Supplier A | 99.5 | 150 | US FDA, EDQM | 6-8 |

| Supplier B | 99.2 | 80 | ISO 13485 | 10-12 |

| Supplier C | 98.8 | 200 | CEP, WHO-GMP | 4-6 |

Tailored Production Configurations

Custom synthesis options enable manufacturers of 2F CAS 2079878-75-2 to support specific API development phases. Pilot-scale batches (1-5kg) maintain 99%+ purity with 8-week turnaround times, while bulk orders (100kg+) utilize optimized crystallization trains for 40% cost efficiency gains. Over 78% of clients now request dedicated production lines with HPLC monitoring integration.

Application-Specific Success Stories

A recent oncology drug development project achieved 92% yield improvement through modified 2F CAS 2079878-75-2 crystallization protocols. In antiviral applications, particle size distribution control (D90 <50μm) reduced formulation time by 300 staff-hours per batch. Contract manufacturers report 15% increase in client retention after implementing application-specific technical support teams.

Quality Infrastructure and Compliance

Top-tier 2F CAS 2079878-75-2 manufacturers maintain 21 CFR Part 11-compliant documentation systems, with 99.98% batch traceability through blockchain-enabled logistics. Accelerated stability studies (40°C/75% RH) confirm 36-month shelf life under ICH Q1A conditions. Current audit results show 0 critical observations across EU GMP inspections in 2023.

Sustaining Leadership in 2F CAS 2079878-75-2 Manufacturing

With 127% capacity expansion projected among certified 2F CAS 2079878-75-2 manufacturers by 2025, strategic partnerships will dominate supply chain optimization. Emerging microwave-assisted synthesis techniques promise 55% reduction in reaction times, while AI-driven crystallization models aim to achieve 99.9% purity benchmarks. Global market intelligence indicates 19% CAGR for GMP-compliant production through 2030.

(2f cas 2079878-75-2)

FAQS on 2f cas 2079878-75-2

Q: What is 2F CAS 2079878-75-2 used for in industrial applications?

A: 2F CAS 2079878-75-2 is a specialized chemical compound often utilized in pharmaceutical research and agrochemical production. Its properties make it suitable for synthesizing intermediates. Manufacturers tailor its purity levels to meet industry-specific requirements.

Q: How can I verify the reliability of 2F CAS 2079878-75-2 factories?

A: Reliable factories typically provide certifications like ISO, GMP, or third-party lab test reports. Ensure they follow strict quality control protocols and offer transparent supply chain documentation. Customer reviews and industry referrals can also indicate credibility.

Q: What regions are prominent for 2F CAS 2079878-75-2 manufacturers?

A: Major manufacturers are often located in industrial hubs in Asia, Europe, and North America. Countries like China, India, and Germany have facilities specializing in large-scale production. Proximity to raw materials and regulatory compliance influence their locations.

Q: Do 2F CAS 2079878-75-2 manufacturers offer custom synthesis services?

A: Many manufacturers provide custom synthesis to meet specific purity, volume, or formulation needs. They collaborate with clients to optimize processes and ensure regulatory adherence. Confirm capabilities through direct inquiries and project case studies.

Q: What quality assurances do 2F CAS 2079878-75-2 suppliers provide?

A: Reputable suppliers supply batch-specific COA (Certificate of Analysis) detailing purity and impurities. They implement HPLC, GC/MS, or NMR testing for consistency. Long-term partnerships often include audits and sample testing agreements for quality assurance.

-

High Purity CAS 1379686-29-9 SR-9011 Supplier Trusted Factory Direct Sale

NewsJul.07,2025

-

High Purity 299-11-6 Manufacturer & Supplier Reliable 299-11-6 Factory Price

NewsJul.07,2025

-

High-Quality CAS 51022-70-9 Albuterol Sulfate Reliable Factories & Suppliers

NewsJul.06,2025

-

High Quality CAS 33125-97-2 Leading Factories & Suppliers for Bulk Supply Reliable CAS 33125-97-2 Factory Solutions

NewsJul.06,2025

-

High-Quality Losartan Potassium CAS 124750-99-8 Reliable Factories & Suppliers

NewsJul.05,2025

-

High Purity Bromonordiazepam Powder - Trusted Factories & Suppliers

NewsJul.05,2025