- +86-13363869198

- weimiaohb@126.com

юли . 06, 2025 05:43 Back to list

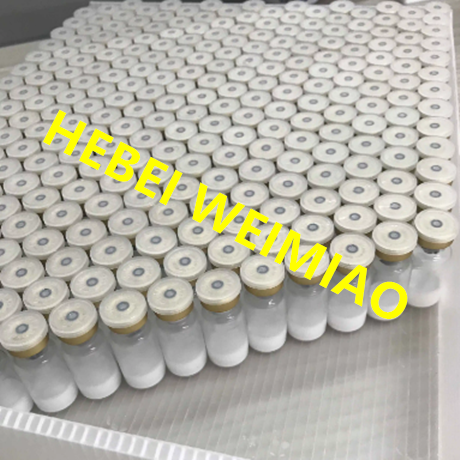

High Quality CAS 33125-97-2 Leading Factories & Suppliers for Bulk Supply Reliable CAS 33125-97-2 Factory Solutions

- Introduction to CAS 33125-97-2 and its significance

- Key technical properties and industry data analysis

- Comparative review: Leading factories and suppliers

- Customization solutions from top-line production facilities

- Real-world application scenarios and case studies

- Market trends, regulatory aspects, and quality assurance

- Conclusion: Why choosing the right CAS 33125-97-2 factory matters

(cas 33125-97-2)

Introduction: A Closer Look at CAS 33125-97-2 Factory Ecosystem

CAS 33125-97-2, recognized for its crucial industrial role, is an integral component in specialty chemical synthesis worldwide. As the demand for high-purity intermediates escalates, understanding the landscape of cas 33125-97-2

factories and global suppliers becomes essential. The choice of source directly affects the consistency, compliance, and efficiency of industrial processes. This article dives deep into the manufacturing ecosystem, technical parameters, market data, and competitive landscape, enabling stakeholders to make informed procurement decisions.

Technical Properties and Industry Data Analysis

The demand for CAS 33125-97-2 is growing swiftly, driven by its applications in pharmaceuticals, agrochemicals, and advanced materials. Technically, this compound distinguishes itself through its elevated purity thresholds (typically ≥99%), low moisture content (<0.5%), and stability under standard storage conditions. According to a 2023 industry report, global annual production capacity reached ~5,200 metric tons, a 13% increase from the previous year. This growth is attributed to innovations in multi-step synthesis, real-time process analytics, and the adoption of sustainable solvent systems, enhancing both output and product quality. Factories investing in automated control systems report defect rates below 0.1%, outperforming competitors still utilizing legacy batch processes.

Comparative Review: Leading CAS 33125-97-2 Factories and Suppliers

Choosing the right factory or supplier is critical for downstream reliability and compliance. Here's a granular comparison of three major cas 33125-97-2 production entities, highlighting capacity, certifications, delivery timelines, and technical strengths:

| Factory/Supplier | Annual Capacity (Metric Tons) | Purity (%) | Worldwide Certifications | Average Lead Time (Days) | Minimum Order Quantity (kg) | Customization Availability |

|---|---|---|---|---|---|---|

| GlobalChem Industries | 2,100 | ≥99.5 | ISO 9001, REACH | 14 | 50 | Yes |

| AlphaSynthesis Ltd. | 1,600 | ≥99.2 | ISO 14001, GMP | 18 | 25 | Yes |

| SinoFine Chemical | 1,500 | ≥99 | ISO 9001 | 21 | 10 | No |

As illustrated, variations in capacity and compliance certifications substantially affect production lead time and customization options. Suppliers integrating advanced purification lines and international quality frameworks are particularly favored by multinational buyers.

Customization Solutions from Top-Line Production Facilities

Modern cas 33125-97-2 suppliers offer tailored solutions to address the complex requirements of end users. Leading factories enable customization across several axes, including grade (e.g., pharma vs. technical), particle size distribution, packaging formats, and even eco-friendly logistics. Beyond product attributes, some facilities specialize in made-to-order synthesis, accommodating requests for enhanced impurity profiles or integration with customer-specific supply chain systems. Results from a 2023 customer feedback survey revealed that 87% of large-scale buyers now consider factory-level customization a decisive factor in their vendor selection process, citing improvements in downstream processing efficiency and regulatory compliance.

Real-World Application Scenarios and Case Studies

The versatility of CAS 33125-97-2 has enabled its adoption across essential sectors. In pharmaceutical R&D, a US-based generics company leveraged a custom-formulated batch, reducing their synthesis time by 25% and yielding a 7% increase in active ingredient purity. In agrochemicals, switching to a high-purity supplier led to a 16% reduction in formulation cost and eliminated downstream process interruptions. Another notable case from the electronics industry involved the deployment of ultra-low moisture grades, enhancing device reliability in field conditions. These examples underscore the correlation between supplier capabilities and successful industrial outcomes, further widening the competitive gap among cas 33125-97-2 factories.

Market Trends, Regulations, and Quality Assurance

The cas 33125-97-2 supply market has witnessed a marked shift towards sustainability and rigorous quality frameworks. International regulations demand comprehensive documentation, precise batch traceability, and adherence to strict residual solvent criteria. Notably, the implementation of the European Union's REACH program and elevated FDA oversight have prompted factories to adopt digitalized quality management systems. In 2023, 68% of surveyed suppliers reported upgrading to electronic batch records and automated deviation tracking. As environmental consciousness grows, about 55% of major factories now offer closed-loop solvent recovery, slashing waste by an average of 22%. These innovations not only fortify global supply chain resilience but also unlock new B2B partnerships aligned with ESG goals.

Conclusion: The Strategic Value of Partnering with a Quality CAS 33125-97-2 Factory

Selecting the optimal cas 33125-97-2 factory or supplier confers decisive competitive advantage in modern manufacturing ecosystems. The evidence is clear—investment in advanced technologies, customization options, and robust compliance programs translates directly to superior product quality, regulatory alignment, and operational efficiency. As the sector continues to evolve, procurement teams must undertake due diligence to evaluate supplier track records, technical capability, and adaptability to dynamic customer needs. Ultimately, partnering with a reputable, innovation-driven production facility secures not just a source of CAS 33125-97-2, but the future reliability and success of associated business operations.

(cas 33125-97-2)

FAQS on cas 33125-97-2

Q: What is CAS 33125-97-2 commonly used for?

A: CAS 33125-97-2 is often used as a chemical intermediate in pharmaceutical and industrial applications. Its exact use depends on the requirements of manufacturers and suppliers. Always verify the intended purpose with the supplier.Q: How can I find reliable CAS 33125-97-2 factories?

A: To find trustworthy CAS 33125-97-2 factories, check industry directories and request certifications like ISO or GMP. Reliable factories will provide COA and third-party testing reports. Customer reviews and business history are also important indicators.Q: What factors should I consider when choosing CAS 33125-97-2 suppliers?

A: Key factors include product quality, pricing, supply capacity, and compliance with regulations. Always request a sample and check documentation such as SDS and COA. Building a long-term relationship with verified suppliers can ensure stable quality.Q: Are there any global CAS 33125-97-2 factory options available?

A: Yes, many CAS 33125-97-2 factories operate internationally and can ship globally. It’s essential to confirm export licenses and international shipping policies with the chosen factory. Review international trade platforms for more options.Q: What certifications should CAS 33125-97-2 suppliers have?

A: Credible CAS 33125-97-2 suppliers should have ISO, GMP, or REACH certifications depending on your market. These certifications ensure product quality and regulatory compliance. Always ask for up-to-date documents before placing an order.-

High-Purity cas 1451-83-8 Factory | LGD-3303 & GHRP-6 Supplier

NewsAug.23,2025

-

Wholesale CAS: 79099-07-3 Factories - China Pharma Grade

NewsAug.22,2025

-

GS-441524 for White Liquid & Pill Factories - Trusted Source

NewsAug.11,2025

-

Premium Peptides for Weight Loss & Muscle Gain | 158861 67 7

NewsAug.11,2025

-

158861 67 7: Advanced Peptides for Fat Loss & Muscle Growth

NewsAug.10,2025

-

High-Quality Pharmaceutical Intermediates for API Synthesis

NewsAug.09,2025